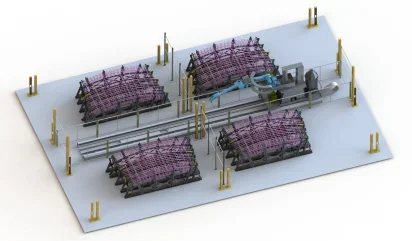

Touted as a breakthrough in robotic welding technology, the MEGA WELDMATE is turning heads across engineering circles for its unique blend of automation, flexibility, and precision — all wrapped into one robust system.

Ulrich Deichmann, CEO, says: “Automating rebar welding has long been a challenge due to irregular shapes, ribbed surfaces, and fabrication inaccuracies. With over 40 years in rebar, we developed our Mega WeldMate system in 2020 using vision and high-speed cameras to identify weld points in milliseconds—even without perfect jigs. Our software compensates for deviations, guiding the robot to complete strong, precise welds in seconds. For tunnel segments—complex and time-consuming to fabricate manually—it’s a game-changer. We can produce a standard segment in under 30 minutes.”

A New Standard in Versatility

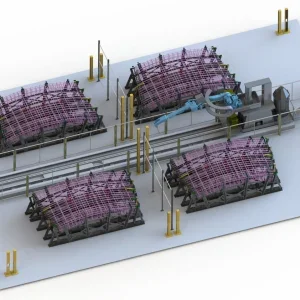

What truly sets MEGA WELDMATE apart is its industrial-grade versatility. Built to meet the demands of large-scale operations, the system handles a broad range of materials and configurations — from 2D bar mats and standard mesh, to heavy and mega mesh. It also excels at welding 3D cages and intricate structural components, all with a level of accuracy that rivals the finest hand-crafted welds.

At the heart of this adaptability lies its compatibility with both standard jigs and custom-designed jigs developed by GMT Robotics, allowing fabricators to shape and weld with remarkable control and creativity.

Engineering Beyond the Expected

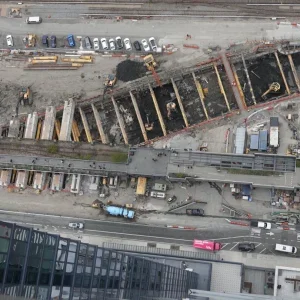

But the MEGA WELDMATE isn’t content with just mastering the fundamentals. This robot is designed to tackle complex structural challenges — including the welding of curved 2D and 3D components. With the appropriate jig setup, it can even take on the demanding task of tunnel segment welding — a feat few robotic systems can match.

It’s this ability to handle bespoke tasks with ease that positions MEGA WELDMATE as more than just another tool in the workshop — it’s a comprehensive solution for today’s most intricate fabrication needs.

Welding Tomorrow, Today

For companies seeking to stay ahead in a competitive, tech-driven manufacturing landscape, the MEGA WELDMATE represents more than innovation — it’s a vision of the future, now fully realized. As automation continues to reshape the industry, GMT Robotics’ latest offering ensures that craftsmanship and technology don’t just coexist — they evolve together.

In short, for those in search of precision, performance, and potential, MEGA WELDMATE may very well be the welding solution they’ve been waiting for.