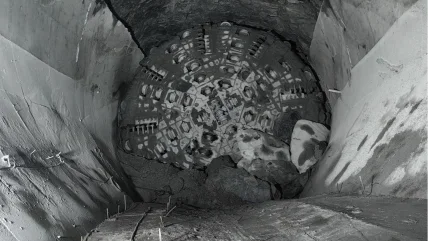

The first diversion inclined shaft at China Pingjiang Pumped Storage Power Station achieved full breakthrough on June 6.

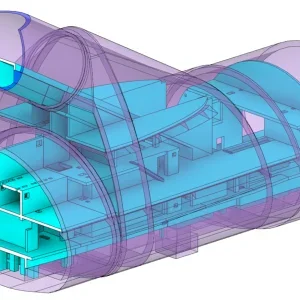

The challenge was completed by TBM Tianyue, which CRCHI (China Railway Construction Heavy Industry Co) says it the world’s first large-inclination, large-diameter, adjustable-diameter hard rock TBM for inclined shafts. The TBM dug the shaft on a 50-degree slope, while adjusting its excavation diameter from 6.5m to 8m.

TBM Tianyue is 87m long, weighs 900 tons and has more than 10,000 parts. It operates on 50-degree inclines, moving upwards, and can achieve full-section excavation and primary support in one go for two-level water diversion inclined shafts. Its tunnelling speed is three times faster than conventional methods.

The No. 1 diversion inclined shaft spans 1,337.9m. Its design of a wider top and narrower bottom features an 8m upper section to reduce flow velocity and prevent cavitation damage under low-pressure conditions, and a 6.5m lower section that cuts steel use in high-pressure zones by over 30% while reducing deep, large chamber excavation risks.

The TBM’s triple-gripping hydraulic interlock system conquered the 50-degree slope. Three sets of grippers anchored to the shaft wall formed an “anti-slip triangular matrix” through cylinder linkage. During boring, mid and rear grippers provided counter-thrust while alternating re-gripping every 1.5m. CRCHI says this interlocked mechanism ensured stable ascent, slashing construction time and enhancing safety.

In designing the machine, CRCHI considered the excavation capabilities and structural design for two large spans with different diameters. It achieved the first breakthrough in convertible cutting wheel edge design and expandable shield technology, complemented by a machine host lifting and diameter-changing device.

CRCHI says the entire diameter-changing process is safe and efficient, allowing a single set of equipment to tunnel different diameters, significantly reducing costs. This is akin to equipping the TBM with an “extendable skeletal structure”, the company says.

It added that the technology had improved the construction environment and accumulated valuable experience for the mechanised construction of pumped storage power stations.