ABSTRACT

Since the 1950s, numerous rock mass classification systems (RMCS) have emerged for applications such as tunnelling, mining, and slope engineering. The continued proliferation of these systems reflects the complexity of the issue and the absence of a universally accepted approach within the rock engineering community. This review offers an up-to-date examination of the global utilisation of RMCS across applications such as tunnels, caverns, mining slope stability, and more.

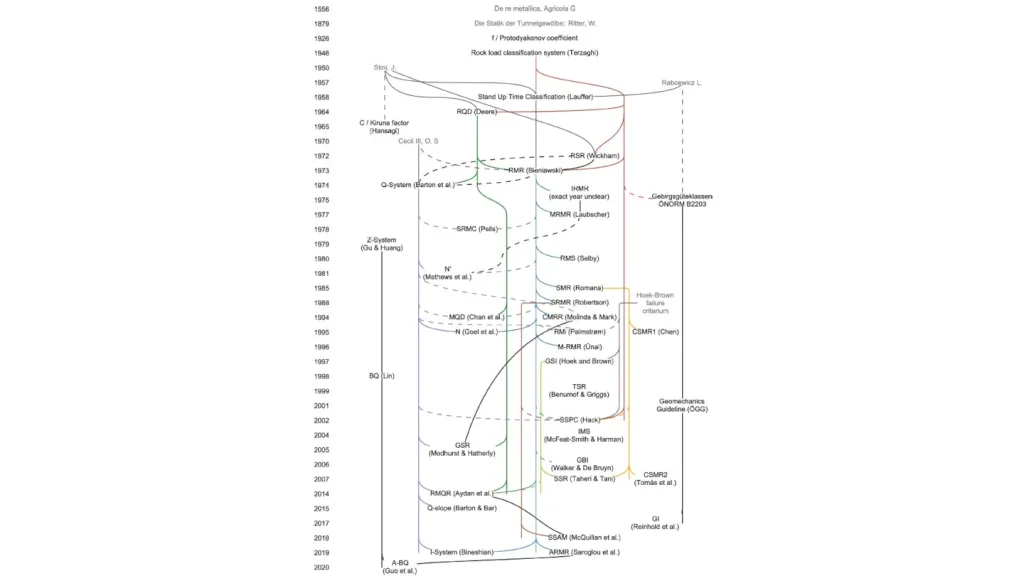

A ‘family tree of rock mass classification systems’ is presented that traces their evolution over the decades. The family tree illustrates a prolific period of system development between 1970 and 2000, followed by a decline in progress and increasing specialisation of systems. Based on surveys within the rock engineering community carried out between 2022 and 2024, the dominant systems for underground engineering and slope-related tasks were found to be GSI, RMR, and the Q-system, which have demonstrated their practical efficacy over five decades.

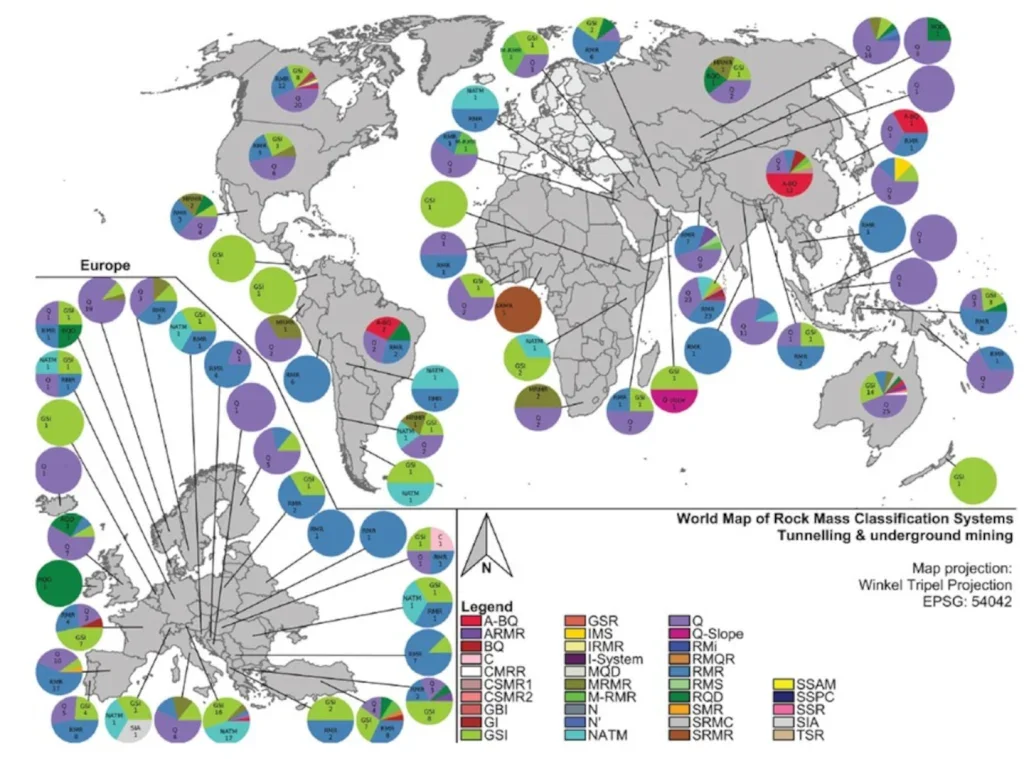

Based on the surveys, ‘world maps of rock mass classification’ have been produced that visualise the international RMCS distribution. However, the survey shows that only some new or derived systems developed in the last 25 years have gained global acceptance. The paper closes with an outlook to possible future developments in rock mass classification and characterisation.

Highlights

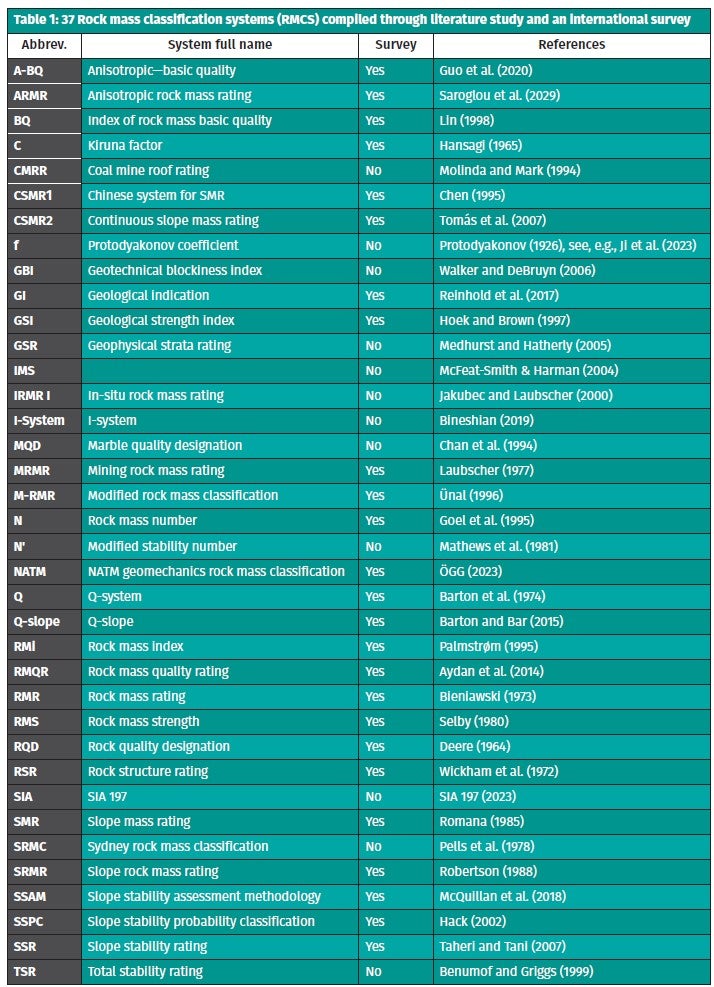

- A comprehensive compilation of 37 rock mass classification systems, created by literature research and international surveys.

- A family tree of rock mass classification systems is presented, showing the main development strands and derived systems.

- Mapping shows the global distribution of rock mass classification systems for underground engineering and slope engineering.

- Discussion of ways to move forward with rock mass classification, considering modern technology and scientific practices.

1 INTRODUCTION

Rock mass is comprised of the intact rock material together with discontinuities and weathering zones, and cavities with liquid or gaseous infilling, often with anisotropic properties.

Considering this geological material and its complex properties, rock engineering design and construction are inherently challenging.

In response, engineers developed a plethora of systems throughout the decades to classify rock mass into discrete classes, often based on assessed and computed continuous metrics, which help to communicate rock mass conditions and ease the rock engineering design process.

Today, dozens of rock mass classification systems (RMCS) exist which is symptomatic of the underlying challenge of describing this natural material. Besides geological complexity, the plethora of existing RMCS can also be attributed to the development of national systems, adaptations to machine logistics, contract regimes, and local rock engineering practices. Ongoing technical debates among scholars and practitioners (Daller et al. 1994; Riedmüller and Schubert 1999; Anagnostou and Pimentel 2012) show that the community has not yet found an optimum solution to that problem.

This contribution aims to provide a global overview of the current state of rock mass classification as of 2024. It provides the rock engineering community with two main products:

- a ‘family tree’ of RMCS that relates all compiled systems to each other. This family tree facilitates a discussion of RMCS from a historical perspective as well as identification of trends, developments, research gaps, and allows to estimate future directions.

- Surveys to investigate the international distribution of RMCS were conducted among the rock engineering community, and based on the results, ‘world maps’ of rock mass classification were created. A preliminary version of this survey was presented in Erharter et al. (2023). However, the herein presented results are more comprehensive as they include 435 more survey responses, thus covering larger parts of the world, and also present the results in more detail. Through the survey and additional literature research, a list of 37 RMCS for different underground and slope engineering purposes was set up, which is the most comprehensive overview of RMCS to date.

2 HISTORICAL DEVELOPMENT OF ROCK MASS CLASSIFICATION SYSTEMS

The earliest systems for classifying geological formations have their roots in past centuries and initially arose from simple attempts to organise and record geological structures and were often related to mining activities. As also mentioned in Aydan et al. (2014), presumably the oldest formerly accessible RMCS was presented in Agricola (1556)—’De Re Metallica’ who differentiates four types of ore:

- “I call that ore “crumbling” which is composed of earth, and of soft solidified juices;”

- “that ore ‘hard’ which is composed of metallic minerals and moderately hard stones.”

- “I call that ore ‘harder’ when with those I have already mentioned are combined various sorts of quartz, or stones which easily melt in fire of the third degree, or pyrites, or cadmia, or very hard marble.”

- “I call that ore ‘hardest’, which is composed throughout the whole vein of these hard stones and compounds.”

These first attempts formed the natural scientific and technical basis for a modern identification and categorisation of soil and rock.

After pioneering tunnelling work in the 19th Century (Ritter 1879), the first ‘modern’ work about RMCS was conducted independently by Protodyakonov and Terzaghi. Protodyakonov introduced a classification system (Protodyakonov (1926) see also Ji et al. (2023)) that is considerably older than other known systems, providing initial insights critical for the development of rock mass classification in the fields of tunnelling and mining engineering.

Protodyakonov’s methodology accounted for various factors influencing rock mass behaviour, including the existence and condition of discontinuities. Terzaghi’s contributions to geotechnical engineering were marked by his capacity to integrate empirical data with theoretical concepts in soil and rock mechanics. His research in the 1920s and 1930s laid the theoretical groundwork for understanding the stress behaviour of soil and rock, later influencing rock mechanics and tunnelling practices (Terzaghi 1946).

In tunnelling-specific developments, Stini became a key figure in rock mechanics and tunnelling, providing essential insights into the behaviour of rock mass during tunnel excavation (Stini 1950).

Rabcewicz is credited with laying the conceptual groundwork for the New Austrian Tunneling Method (NATM), introducing a strategy that tailored the support system to geotechnical conditions encountered during tunnel excavation (Rabcewicz 1957).

The development of RMCS for tunnelling from the 1950s to the 2000s was characterised by significant innovations. In addition to Terzaghi’s contributions, Lauffer’s introduction of the concept of ‘standing time’ (Lauffer 1958) was a key moment in the dialogue on rock classification systems.

Deere’s development of the Rock Quality Designation (RQD) in 1963 focused on quantifying rock quality based on drill cores only. Subsequent decades saw the creation of comprehensive systems.

Bieniawski’s Rock Mass Rating (RMR) system, introduced in 1973, was revolutionary in offering a numerical rating correlated with tunnel support recommendations. Barton’s Q-system, starting in 1974, provided a detailed assessment framework for tunnelling projects, emphasising empirical data’s utility across varied rock conditions. The introduction of the Geological Strength Index (GSI) by Hoek and Brown (1997) marked a move towards a more direct visual, field-adapted, evaluation of rock mass properties without any direct numeric inputs.

Slope-specific developments have been driven by the unique challenges and objectives inherent in slope stability analysis. The divergence between classification systems for slopes and tunnels reflects the distinct stability issues encountered in each domain. While the GSI finds application in both tunnelling and slope stability analysis, its use in slopes often focuses more on the structural complexity and surface condition of the rock mass. The Slope Mass Rating (SMR) system, developed by Romana (1985), adapted the RMR system for rock slope assessment (SRMR), while the Q-system was adapted to Q-slope by Barton and Bar (2015).

A remarkable parallel development that seems detached from other RMCS that predominantly originate from the ‘West’ is the Chinese ‘Basic Quality’ (BQ) system that today is finding significant application internationally.

BQ goes back to the ‘Z-System’ developed by Gu and Huang (1979) and was subsequently adopted in the Chinese standard (Lin 1998; GB 50218–2014 (2014)). Further development goes into BQ, and it was recently modified to also account for anisotropy, thus becoming the ‘anisotropic-BQ’ system (A-BQ) (Guo et al. 2020) which combines BQ and Anisotropic RMR (ARMR) (Saroglou et al. 2019).

Efforts to construct a ‘family tree’ of rock mass classification systems have highlighted the existence of five main strands, illustrating both the pioneering figures behind these systems and their interconnected evolution that often gave rise to multiple follow-up RMCS. These strands are:

- the rock load classification system strand (dark red in Figure 1) being the base for/or influencing six follow-up systems;

- RQD strand (green in Figure 1) being the base for/ or influencing five follow-up systems;

- RMR strand (blue in Figure 1) being the base for/or influencing 17 follow- up systems among which the SMR and SRMR served as a base for further RMCS themselves (marked as brown and orange strands in Figure 1);

- Q-strand (purple in Figure 1) being the base for/or influencing 11 follow-up systems; and,

- GSI strand (light green in Figure 1) being the base for/or influencing at least two more systems.

As mentioned above, the A-BQ system lies on its own path and can be seen as a solitary development that only recently merged with the RMR strand.

The same goes for the rock mass classification according to the ‘ÖGG geomechanical design’ guideline that goes back to the ‘Gebirgsgüteklassen’ that was introduced in the ÖNORM B 2203 (1975) and is connected to the New Austrian Tunnelling method. The ‘ÖGG geomechanical design’ is generally different from other RMCS, as it is based on the idea that every rock mass is unique and should get its own classification to be able to account for different failure modes and not oversimplify the geology to one single number. The ‘Geological Indication’ (GI) from Reinhold et al. (2017) is one recent offspring of this concept and constitutes a rock mass behaviour-based RMCS developed for one construction lot of the Brenner Base Tunnel project.

The historical reconstruction shows that system development took a significant upturn between 1970 and 2000, with 21 RMCS developed in that timeframe. Many of these systems are still in use today and formed the basis for more application-specific systems developed in the last two decades.

It needs to be noted that a certain subjective assessment affects the design of the whole family tree, as many authors of RMCS do not explicitly write which prior systems have had the primary influence on their work. Furthermore, several systems have only been published as part of conference proceedings, severely limiting their accessibility, and their origin had to be retraced through third-party literature. Lastly, even though we see the compilation of RMCS in Table 1 as one of the most comprehensive ones up to today, it cannot be ruled out that even more RMCS exist.

3 SURVEY METHODOLOGY

Two surveys were conducted with the online tool ‘Microsoft Forms’. The surveys followed two goals: (i) investigate the international distribution of RMCS; and, (ii) identify RMCS that the authors were unaware of before. Both surveys were identical in their setup and comprised one main question and three choices:

- Main question and description: “Which rock mass classification system have you used in this country the most?” A description was given that specifies: “Please select a rock mass classification system, a country and an application below. You will be able to submit multiple answers for different systems.”

- Choice 1: “Select a rock mass classification system (alphabetically sorted) or enter a new one”. Here, participants could choose one of the RMCSs of Table 1 which are indicated as ‘yes’ in the column “Included in survey questions”. These are the systems that the survey authors originally included in their questionnaire. Participants also had the choice to indicate “other” and specify a new RMCS (indicated as ‘no’ in the column “Survey” in Table 1).

- Choice 2: “Country”. Here participants were able to indicate in which country they have applied the RMCS chosen under Choice 1.

- Choice 3: “Application of System”. Here, participants could choose what they have used the system for: Tunnels and Caverns; Slopes—Civil Engineering; Slopes—Mining; Slopes—Natural; Underground Mines; Foundations; and, Oil and Gas reservoirs.

A combination of answers would be in the form: RMCS— country—application. One possible combination would be: Q-System—Norway—Tunnels and Caverns. After submitting a combination, participants were thanked for their contribution and encouraged to submit more suggestions if they knew additional combinations.

The first survey was open from September to November 2022 and preliminary results were presented at the Congress of the International Society of Rock Mechanics (ISRM) in Salzburg, Austria, in 2023 (Erharter et al. 2023). The first survey collected a total of 798 suggestions. The second survey was launched to collect more responses and was open from October 2023 to February 2024 and collected another 435 suggestions, leading to a total of 1233 suggestions.

The top 10 countries in terms of submitted RMCS suggestions were Australia, India, Canada, Spain, Austria, Indonesia, China, Kazakhstan, Turkey and Pakistan. The inhomogeneous number of suggestions per country restricts analyses of absolute numbers of RMCS globally as the numbers of submitted votes depend mostly on the achieved outreach of the survey and no other geographical numbers such as population sizes.

The collected suggestions had to be slightly postprocessed to facilitate further analyses. This required harmonising new suggestions of RMCS as a response to ‘Choice 1’ (see above) and included: (i) removing 12 unusable suggestions that were not connectable to any identifiable system; and, (ii) merging of suggestions that refer to the same RMCS.

All RMCS that are included in this study are given in Table 1, of which 25 were actively included in the surveys and an additional 12 were included due to participants’ feedback. This list of 37 RMCS is considered comprehensive and was used for further analyses in this study. The anonymised results (i.e., without response time and original ID of participant and after the abovedescribed processing) of the surveys are given in supplementary data to the original full paper.

4 INTERNATIONAL DISTRIBUTION OF ROCK MASS CLASSIFICATION SYSTEMS

The surveys gave a distribution of RMCS for each application and for each country where submissions were handed in. In contrast to Erharter et al. (2023) where the resulting maps only contained the “majority RMCS” for each country, i.e., the RMCS that is used most in the country, the results were shown in pie charts for every country, such as in Figure 2, which is one of the maps and concerns Tunnelling & Underground Mining.

A further map of pie charts concerns Slope Applications. Due to only 68 submissions for the application Foundations for 30 different countries, no dedicated map was produced. The application Oil and Gas reservoirs was excluded from the study as there was only one submission.

The map of the international distribution of RMCS for underground applications, Figure 2, contains results for 69 countries where suggestions were submitted. It can be seen that the internationally dominating systems are the Q-system (Barton et al. 1974), RMR (Bieniawski 1973), and GSI (Hoek and Brown 1997). However, it is open whether participants use GSI for rock mass classification or only as an intermediate step for rock mass characterisation in the geomechanical design workflow.

The pie charts allow a close-up assessment of individual countries. There are mainly two types of countries (based on countries with > 20 submissions in total):

- countries that split into thirds with two-thirds belonging to two main systems and one-third being comprised of several other systems (e.g., Australia, India, Canada, Austria, Turkey, Pakistan, US, Mexico); and,

- countries where one system dominates with ≥ 50% (e.g., Spain (RMR), Indonesia (RMR), Kazakhstan (Q), China (A-BQ), UK (Q), Italy (Q), Greece (GSI), and Norway (Q)).

The map for the distribution of RMCS for slope application contains responses from 78 countries. GSI seems to be the favoured system for slope application in general and also dominates in several countries, e.g., Australia, Papua New Guinea, Austria, and Turkey. A much more colourful picture emerges compared to that for underground applications with, for example, some countries showing a remarkable variety of systems, e.g., India where three-fourths of the submissions indicated the Continuous Slope Mass Rating (Tomás et al. 2007), Slope Mass Rating (Romana 1985) and RMR, respectively, and the last quarter consists of various other systems. Another example is Mexico, where a third of the submissions indicate the use of GSI, but the rest include RMR, Q-Slope (Barton and Bar 2015), Slope Stability Assessment Methodology (SSAM) (McQuillan et al. 2018), etc., or Peru, where one-third goes to RMR, but the rest is comprised of six other systems.

As in the map for underground applications, the map for slope applications shows that some countries have two dominating systems, and in several others, such as: Kazakhstan where one-third goes to GSI and RMR, respectively, and the rest goes to five other systems; or Spain where two-thirds go to the Slope Mass Rating and GSI, respectively. The other third is comprised of five other systems.

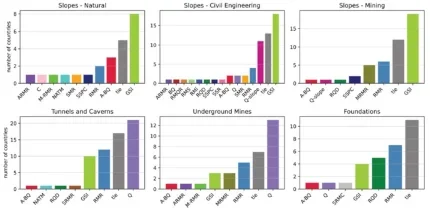

Figure 3 shows bar charts for each investigated application except for Oil and Gas reservoirs, which show in how many countries one RMCS achieved more votes than all other RMCS (i.e., majority vote). In case more than one RMCS received the same number of votes for one country, the country is set to “tie” (e.g., Bolivia received only two submissions for the application Tunnels and Caverns resulting in a tie).

For all applications, a “tie” is either the second most frequent or even most frequent situation, thus indicating that there is no best-fitting system for each investigated application. However, GSI is first place for all three different slope-related applications, and Q-slope, RMR, and A-BQ are also among the top systems.

Despite the “tie” situations, the Q-system ranks number one in applications Tunnels and Caverns and Underground Mines followed by RMR.

For the application in Foundations, RMR reaches second position, behind a tie; RQD and GSI follow RMR. This can indicate that rock mass classification plays a subordinated role in foundation engineering and, rather, parameters such as RQD and GSI used for general rock mass characterisation are in use.

5 DISCUSSION

The world map of rock mass classification (see Figure 2), for Tunnelling & Underground Mining, shows that a large number of RMCS are in use all over the world today. However, we can observe that only a few are majorly used: (a) for slope engineering (GSI, RMR, Q-slope); and, (b) for underground construction (Q, RMR, GSI).

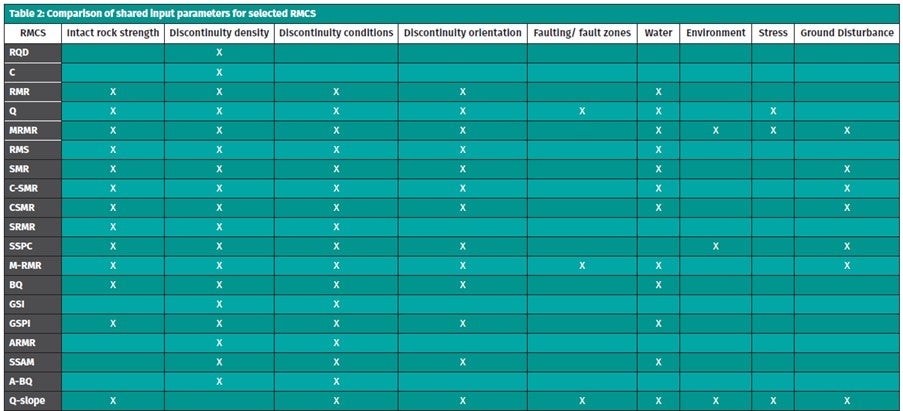

Technically comparing these systems (also including A-BQ due to its dominance in Asian countries) among one another shows that they are considering different parameters that characterise different aspects of the rock mass (see Table 2).

All rock mass classification systems consider the discontinuity density in one way or another (often through RQD), but no other parameter is shared by all. This can be related to the geological background of these systems and, therefore, regional engineering focus points.

The most frequently used RMCS are all at least 25-years old, except for the more recent Q-slope system.

In contrast to constitutive modelling, where newer models tend to require more input parameters (Zhang et al. 2021), RMCS that were developed in the past decade do not show such a trend. For example, both the Q-system and RMR were developed in the 1970s and require six input parameters and recent developments such as Q-slope (Barton and Bar 2015), ARMR (Saroglou et al. 2019) or A-BQ (Guo et al. 2020) also require, respectively, six, six, or two input parameters.

In terms of parameter assessment, most RMCS rely heavily on visual estimations, and some newer developments even highlight that they do not require any measured input quantities (e.g., SSAM from McQuillan et al. 2018). While the practice of relying on subjective, visual assessments is convenient as it exempts rock engineers from having to deal with new technology, it also hinders technology-driven progress in rock engineering. Skretting et al. (2023) for example showed highly user-dependent rock mass classifications if the same tunnel faces are visually assessed by multiple experts.

Furthermore, most RMCS introduce some form of bias related to problems, such as: subjective, low dimensional assessment of parameters; limited or selective choice of case studies used for the system development; or, narrow fields of applications that should not be exceeded. Examples include:

- RQD is subject to sampling bias since it is directionally dependent based on the drilling direction (Deere 1989) and also suffers from other limitations related to its assessment in general (Pells et al. 2017);

- SRMR was introduced based on case studies from only two locations (Robertson 1988); SSAM was developed specifically for coal mine slopes (McQuillan et al. 2018).

Many technical and regulatory factors could be discussed for why there is such a plethora of RMCS today, including:

- the simultaneous use of multiple RMCS for crossvalidation on projects;

- a possible disagreement in the community;

- limited or no governmental regulation and standardisation;

- different international experts bringing their preferred system;

- different geological requirements.

In a bigger picture, however, most RMCS that were developed in the past decade are not conceptually or technologically very different from the ones developed half a century ago. Consequently, some of the new RMCS may not properly address problems in the existing systems, and fundamental research is needed to significantly improve the existing rock mass classification system paradigm. The low adoption rate of new RMCS can, therefore, be related to not offering sufficiently improved results in comparison to their predecessors.

The introduction of modern technology, such as geophysics, drilling data, scanning, and remote sensing for site investigations, has greatly increased the amount of available data as a possible input for rock mass classification and characterisation. While some of these methods, like geophysics, only provide indirect information about the rock mass conditions, they still contribute to give operators a more holistic impression of the rock mass conditions in combination with direct measures, such as drilling or surface scanning. This technology can, therefore, contribute to a closer approximation of the real rock mass conditions and can also contribute to being better aware of existing uncertainties.

Although some RMCS have general correlations with and can be supplemented by data from modern technology, they still require validation with physical access to drill core or rock faces for certain elements (Barton 2002; Bar et al. 2021). No RMCS has yet been developed specifically to integrate with modern technology and digital data.

6 CONCLUSION AND OUTLOOK

A survey about the worldwide use of RMCS shows a considerable diversity of systems in use, while only a few (GSI, RMR, Q-system) are majorly used today. Furthermore, the historical development of RMCS is reconstructed and presented in the form of a family tree that shows that some RMCS served as parents for many new developments (e.g., RMR) but also that there were some parallel developments throughout the decades that only recently started to approach one another (e.g., A-BQ).

While this paper is not the first review of RMCS, it is the first to visually show the diversity in the form of maps and a family tree; it enriches the existing body of knowledge with these graphical components. It is this systematic mapping and historical reconstruction that led to the insight presented in the discussion chapter about the newly developed RMCS, showing minor differences and incremental improvements with respect to the systems developed in the 1950s to 1970s.

While there are several barriers such as different geological- or site-specific conditions, cultural differences, and available technical equipment that make progress challenging, there are several ways to go forward. One way is to further develop existing systems to make them more use-case specific. While this might contribute to the further proliferation of RMCS and make future maps even more colourful, it is questionable if this will ever lead to a groundbreaking improvement in rock engineering. As elaborated in the previous section, incrementally adapting existing RMCS without significant conceptual or technological changes does not seem to answer old challenges.

Consequently, another way is to develop new RMCS that are either generally better or better for specific use-cases than existing ones. A challenge in this endeavour is, however, that the new development of RMCS is inherently dependent on further developments in rock engineering design practices that utilise the output of rock mass classification and characterisation.

A newly developed RMCS is futile if there is no geotechnical design or analysis method that utilises it. Conducting full-scale geotechnical field tests to obtain in-situ mechanical rock mass parameters and probabilistic back analyses from on-site deformation monitoring is seen to play a vital role in developments like that. Furthermore, technical deficits of RMCS need to be identified and addressed before new ones can be developed.

In any case, certain objectives should be fulfilled with the development, as pointed out in Bobet and Einstein (2024): RMCS for engineering design should be:

- economical, yet safe;

- generally applicable and robust or only apply for a well-defined field of application;

- based on parameters that are readily determinable;

- aware of their inherent subjectivity; and,

- based on correct underlying assumptions and models whether they are explicit or implicit.

In addition to these fundamental requirements, we suggest that further or new developments of RMCS are:

- based on openly accessible databases and follow FAIR data principles (Wilkinson et al. 2016) so that developed relationships are comprehensible and retraceable to avoid distrust in the system;

- consider measurable information through modern sensing technology to the largest possible extent and avoid parameters that are only estimated to avoid disputes about subjectivity in the assessment;

- thoroughly describe the system, the involved processing of the dataset used and the data collection process in peer-reviewed scientific papers; and,

- apply modern statistical methods ranging from multivariate statistics, Bayesian statistics to machine learning (ML).

A last way forward could be to move away from rock mass classification approaches in general. However, this requires further developments in rock engineering design practices. Focusing more on rock mass characterisation instead of classification might be a way to more realistically describe the complex geological nature of the rock mass instead of trying to put everything into inherently non-existing classes.

Acknowledgements: Mrs. Timna Plöchl is thanked by the authors for her assistance in creating the family tree of rock mass classification systems.

Declarations (Conflict of interest): The authors have no relevant financial or non-financial interests to disclose.

This paper was originally published online in Rock Mechanics and Rock Engineering Journal, from Springer, in October 2024, under a Creative Commons Attribution 4.0 International Licence (http://creativecommons.org/licenses/by/4.0/ ). Open access funding for original publication of the paper was provided by the Norwegian Geotechnical Institute (NGI). As permitted under the particular open access facility, this version of the original paper has been abridged and edited for space, and images have been adapted to house-style. The original paper is available in full at https://doi.org/10.1007/ s00603-024-04215-8.

REFERENCES

● Agricola G (1556) De Re Metallica: translated from the First latin edition of 1556; translators: Hoover, H.C. & Hoover, L.H.

● Anagnostou, G. & Pimentel, E. (2012) Zu den Felsklassifikationen mit Indexwerten im Tunnelbau. Geotechnik 35:83–93. https://doi.org/10.1002/gete.201100022

● Aydan, Ö., Ulusay, R. & Tokashiki, N. (2014) ‘A New rock mass quality rating system: RMQR and its application to the estimation of geomechanical characteristics of rock masses’. RMRE 47:1255–1276. https://doi.org/10.1007/s00603-013-0462-z

● Bar, N., Borgatti, L., Donati, D., Francioni, M., Salvini, R. & Ghirotti, M. (2021) ‘Classification of natural and engineered rock slopes using UAV photogrammetry for assessing stability’. IOP Conf Ser: Earth Environ Sci 833:12046. https://doi.org/10.1088/1755- 1315/833/1/ 012046

● Barton, N. (2002) ‘Some new Q-value correlations to assist in site characterisation and tunnel design’. Int J Rock Mech Min Sci 39:185– 216. https://doi.org/10.1016/S1365-1609(02)00011-4

● Barton, N. & Bar, N. (2015) ‘Introducing the Q-slope method and its intended use within civil and mining engineering projects’. Proceedings of ISRM’s Eurock 2015 & 64th Geomechanics Colloquium, Austria.

● Barton, N., Lien, R. & Lunde, J. (1974) ‘Engineering classification of rock masses for the design of tunnel support’. Rock Mech 6:189–236. https://doi.org/10.1007/BF01239496

● Bieniawski, Z.T. (1973) ‘Engineering classification of jointed rock masses’. Civil Engineer in South Africa 15(12):335–343.

● Bineshian, H. (2019) ‘I-System: a comprehensive indexing system for ground-structure behaviour classification and characterization’. J Eng Geol 44:73–109.

● Bobet, A. & Einstein, H.H. (2024) Tunnel design methods. CRC Press.

● Chan, Y.C., Ho, K. & Pun, W.K. (1994) ‘A new marble rock mass classification system for the interpretation of karst morphology in Hong Kong’. HKIE Trans 1:1–12. https://doi.org/10.1080/1023697X.1994.10667667

● Chen, Z. (1995) ‘Recent developments in slope stability analysis’. Proceedings of 8th ISRM Congress.

● Daller, J., Riedmüller, G. & Schubert, W. (1994) ‘Zur Problematik der Gebirgsklassifizierung im Tunnelbau’. Felsbau 12:443–447

● Deere, D.U. (1964) ‘Technical description of rock cores for engineering purpose’. Rock Mechanics and Engineering Geology 1(1):16–22.

● Deere, D.U. (1989) ‘Rock quality designation (RQD) after twenty years’. USACE.

● Erharter, G.H., Hansen, T.F., Qi, S., Bar, N. & Marcher, T. (2023) ‘A 2023 perspective on rock mass classification systems’. Proceedings of the 15th ISRM Congress 2023 & 72nd Geomechanics Colloquium.

● GB 50218–2014 (2014) Standard for engineering classification of rock masses. China Planning Press, Beijing.

● Goel, R.K., Jethwa, J.L. & Paithankar, A.G. (1995) ‘Indian experiences with Q and RMR systems’. Tunn Undergr Space Technol 10:97–109. https://doi.org/10.1016/0886-7798(94)00069-W

● Gu, D. & Huang, D. (1979) ‘Classification of rock mass structure and determination of its quality coefficient’. Hydrogeol Eng Geol 8:8–13.

● Guo, S., Qi, S. & Saroglou, C. (2020) ‘A-BQ, a classification system for anisotropic rock mass based on China National Standard’. J Cent South Univ 27:3090–3102. https://doi.org/10.1007/s11771-020-4531-7

● Hansagi, I. (1965) ‘Numerical determination of mechanical properties of rock and of rock masses’. Int J Rock Mech Min Sci Geomech Abstr 2:219–223. https://doi.org/10.1016/0148-9062(65)90014-8

● Hoek, E. & Brown, E.T. (1997) ‘Practical estimates of rock mass strength’. Int J Rock Mech Min Sci 34:1165–1186.

● Jakubec, J. & Laubscher, D.H. (2000) ‘The MRMR rock mass rating classification system in mining practice’. MassMin 2000 Proceedings, Australasian Institute of Mining and Metallurgy.

● Ji, Z., Li, J., Zhang, X. & Song, Z. (2023) ‘A quantitative assessment method for the correlation between rock mass basic quality and Protodyakonov coefficient. Front Earth Sci. https://doi.org/10.3389/feart.2023.1249866

● Laubscher, D.H. (1977) ‘Geomechanics classification of jointed rock masses: mining applications’. Inst. Min. Metall., Trans., Sect. A; (United Kingdom) 86.

● Lauffer, H. (1958) Gebirgsklassifizierung für den Stollenbau. Geologie und Bauwesen 24:46–51.

● Lin, Y. (1998) ‘An introduction of the Chinese standard for engineering classification of rock masses’ (GB50218 – 94):317– 327. https://doi.org/10.1142/9789812839640_0029

● Mathews, K., Hoek, E., Wyllie, D.C. & Stewart, S. (1981) ‘Prediction of stable excavation spans for mining at depths below 1000 meters in hard rock’. CANMET Library & Documentation Services Division.

● McFeat-Smith, I. & Harman, K. (2004) ‘IMS risk evaluation system for financing and insuring tunnel projects’. Tunn Undergr Space Tech- no l 19:334. https://doi.org/10.1016/j.tust.2004.01.030

● Medhurst, T. & Hatherly, P. (2005) ‘Geotechnical strata characterization using geophysical borehole logs’. Proceedings of the 24th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV, 2-4 August 2005, pp 179–186.

● Molinda, G.M. & Mark, C. (1994) Coal mine roof rating (CMRR): a practical rock mass classification for coal mines. U.S. DoI, Bureau of Mines, Information Circular 9387:83.

● NS-EN ISO 14689:2018 (2018) Geotechnical investigation and testing: Identification, description and classification of rock. Standard Norge.

● ÖGG (2023) Richtlinie Geotechnische Planung von Untertagebauten Zyklischer und kontinuierlicher Vortrieb: Gebirgscharakterisierung und Vorgangsweise zur nachvollziehbaren Festlegung von bautechnischen Maßnahmen während der Planung und Bauausführung.

● ÖNORM B 2203 (1975) Untertagebauarbeiten. Österreichisches Normungsinstitut.

● Palmstrøm, A. (1995) ‘RMi-A rock mass characterization system for rock engineering purposes’. Ph.D. thesis, University of Oslo.

● Pells, P.J., Bieniawski, Z.T., Hencher, S.R. & Pells, S.E. (2017) ‘Rock quality designation (RQD): time to rest in peace. Can Geotech J 54:825– 834. https://doi.org/10.1139/cgj-2016-0012

● Protodyakonov, M. (1926) ‘Materials for a fixed position of mining operations: Part I. Mining operations’. Publication of the TsK of Miners Rabcewicz LV (1957) Die Ankerung im Tunnelbau ersetzt bisher gebräuchliche Einbaumethoden. Schweizerische Bauzeitung: 123–131. https://doi.org/10.5169/SEALS-63315

● Rabcewicz, L.V. (1957) ‘Die Ankerung im Tunnelbau ersetzt bisher gebräuchliche Einbaumethoden’. Schweizerische Bauzeitung: 123–131. https://doi.org/10.5169/SEALS-63315

● Reinhold, C., Schwarz, C. & Bergmeister, K. (2017) ‘Development of holistic prognosis models using exploration techniques and seismic prediction’. Geomechanik und Tunnelbau 10:767–778. https://doi.org/10.1002/geot.201700058

● Riedmüller, G. & Schubert, W. (1999) ‘Critical comments on quantitative rock mass classifications’. Felsbau 17:164–167.

● Ritter, W. (1879) ‘Die statik der tunnelgewölbe’. J. Springer, Berlin.

● Robertson, A.M. (1988) ‘Estimating weak rock strength’. Society of Mining Engineering (ed) Proceedings of the SME Annual Meeting, pp 1–5.

● Romana, M. (1985) ‘New adjustment ratings for application of Bieniawski classification to slopes’. Proceedings of International Symposium on the Role of Rock Mechanics, pp 49–53.

● Saroglou, C., Qi, S., Guo, S. & Wu, F. (2019) ‘ARMR, a new classification system for the rating of anisotropic rock masses. Bull Eng Geol Environ 78:3611–3626. https://doi.org/10.1007/s10064-018-1369-4

● Selby, M.J. (1980) ‘A rock mass strength classification for geomorphic purposes: with tests from Antarctica and New Zealand’. zfg 24:31– 51. https://doi.org/10.1127/zfg/24/1984/31

● SIA 197 (2023) Projektierung Tunnel – Grundlagen. SIA.

● Skretting, E., Erharter, G.H. & Chiu, J.K.Y. (2023) ‘Virtual realitybased uncertainty assessment of rock mass characterization of tunnel faces’. Proceedings of 15th ISRM Congress 2023 & 72nd Geomechanics Colloquium, Austria.

● Stini, J. (1950) Tunnelbaugeologie. Springer, Vienna.

● Taheri, A. & Tani, K. (2007) ‘Rock slope design using slope stability rating (SSR)‚ application and field verifications. The 1st Canada– U.S. Rock Mechanics Symposium, pp 215–221. https://doi.org/10.1201/NOE0415444019-c27

● Terzaghi, K. (1946) ‘Rock defects and loads on tunnel supports: introduction to rock tunnelling with steel supports’.

● Tomás, R., Delgado, J. & Serón, J.B. (2007) ‘Modification of slope mass rating (SMR) by continuous functions’. Int J Rock Mech Min Sci 44:1062–1069. https://doi.org/10.1016/j.ijrmms.2007.02.004

● Ünal, E. (1996) ‘Modified rock mass classification: M-RMR system. Milestones in rock engineering: The Bieniawski jubilee collection’. Rotterdam, Balkema, pp 203–223.

● Walker, D., DeBruyn, I. (2006) ‘Geotechnical blockiness index: a systematic geotechnical mapping method for underground and open pit mines’. Proceedings of 7th Australia–New Zealand Young Geotechnical Professionals Conference.

● Wickham, G.E., Tiedemann, H.R. & Skinner, E.H. (1972) ‘Support determinations based on geologic predictions’. RETC 1972 Proc, pp 43–64

● The FAIR Guiding Principles for scientific data management and stewardship, 2016. Sci Data 3:160018. https://doi.org/10.1038/sdata.2016.18

● Zhang, P., Yin, Z-Y. & Jin, Y-F. (2021) ‘State-of-the-art review of machine learning applications in constitutive modeling of soils’. Arch Comput Methods Eng 28:3661–3686. https://doi.org/10.1007/s11831-020-09524-z