On 20 March 2025, Bekaert had the pleasure of collaborating with the British Tunnelling Society Young Members (BTSYM) to deliver an engaging and informative workshop for young engineers.

The event, held at The Institution of Civil Engineers (ICE), saw a full house with 20 enthusiastic attendees eager to learn about the latest advancements in steel fibre reinforced concrete (SFRC) and its applications in tunnelling.

We had the opportunity to cover different types of applications for steel fibres in tunnelling construction, share insights from global case studies, design methodologies, and innovations in crack width control with the use of steel fibre reinforced concrete, that are reshaping how we approach concrete durability, sustainability, and performance.

IN-DEPTH

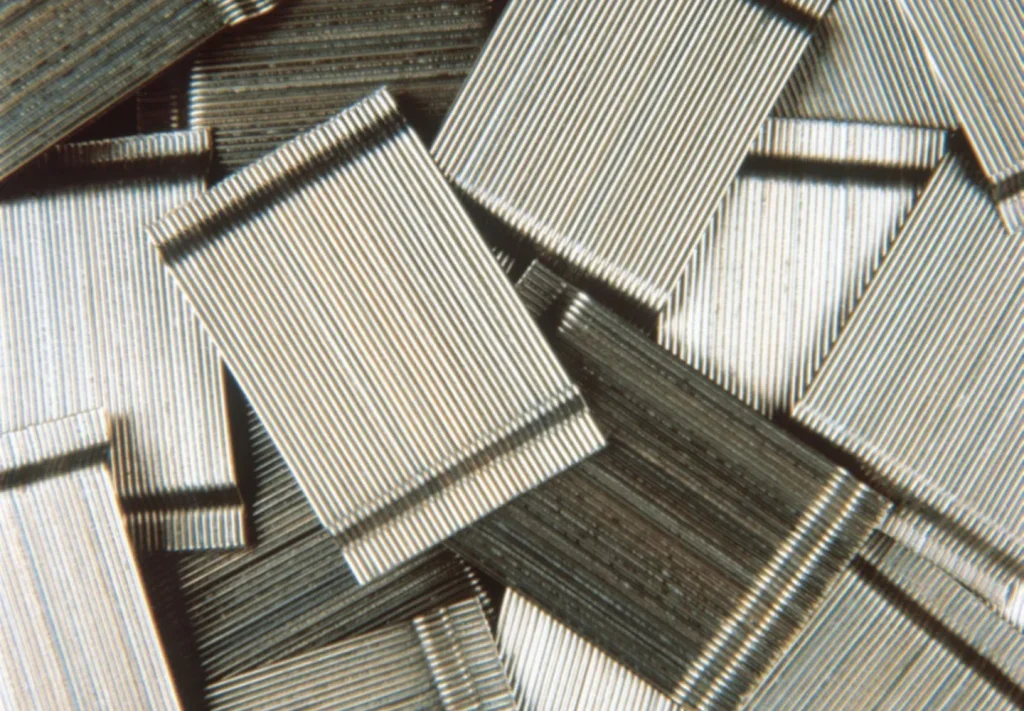

The workshop kicked off with an introduction to Bekaert and an overview of SFRC, highlighting its tensile strength, crack control, ductility, anchorage, and aspect ratio. Attendees were introduced to various testing methods, including EN 14651, EN 14488-5 for energy absorption, and EN 14488-3 method B.

The session also covered the transition from temporary to permanent sprayed concrete linings, emphasising the benefits of SFRC in these applications.

Following a short coffee break, the focus shifted to low carbon segmental lining. The presentation detailed the advantages of SFRC in reducing carbon footprints and showcased several real-world examples.

Crack control design principles and new applications, such as cut-and-cover tunnels, were also discussed.

Quality control methods and equipment’s, including the wash-out test, EyeD machine, and UPC device, were highlighted to ensure the highest standards in construction.

The practical session, held in the afternoon, was a highlight for many attendees. Participants engaged in exercises using Bekaert’s software to design segmental linings, hybrid designs for cut-and-cover tunnel slabs/walls, and moment capacity designs for slope stabilisation and sprayed concrete linings. These exercises provided valuable insights into the practical aspects of tunnel lining design and the innovative use of SFRC.

CASE STUDIES

During our presentation, we covered a few case studies highlighting the advantages of designing with steel fibres versus traditional reinforcement and demonstrating the benefits in terms of carbon savings, reduced concrete cover and enhanced durability.

Some case studies were presented, as follows:

Grand Paris Express Line 16 (France)

- Application: Precast segmental lining

- Highlights: 11,000 tons of CO₂ saved per 10km

- Key Focus: Carbon reduction, logistics efficiency

Montreal Blue Line Extension (Canada)

- Application: Precast segmental lining

- Highlights: 47% total CO₂ savings (13,177 tons), 35% per m3

- Key Focus: Carbon reduction and reduced concrete cover

IJboulevard Central Station, Amsterdam

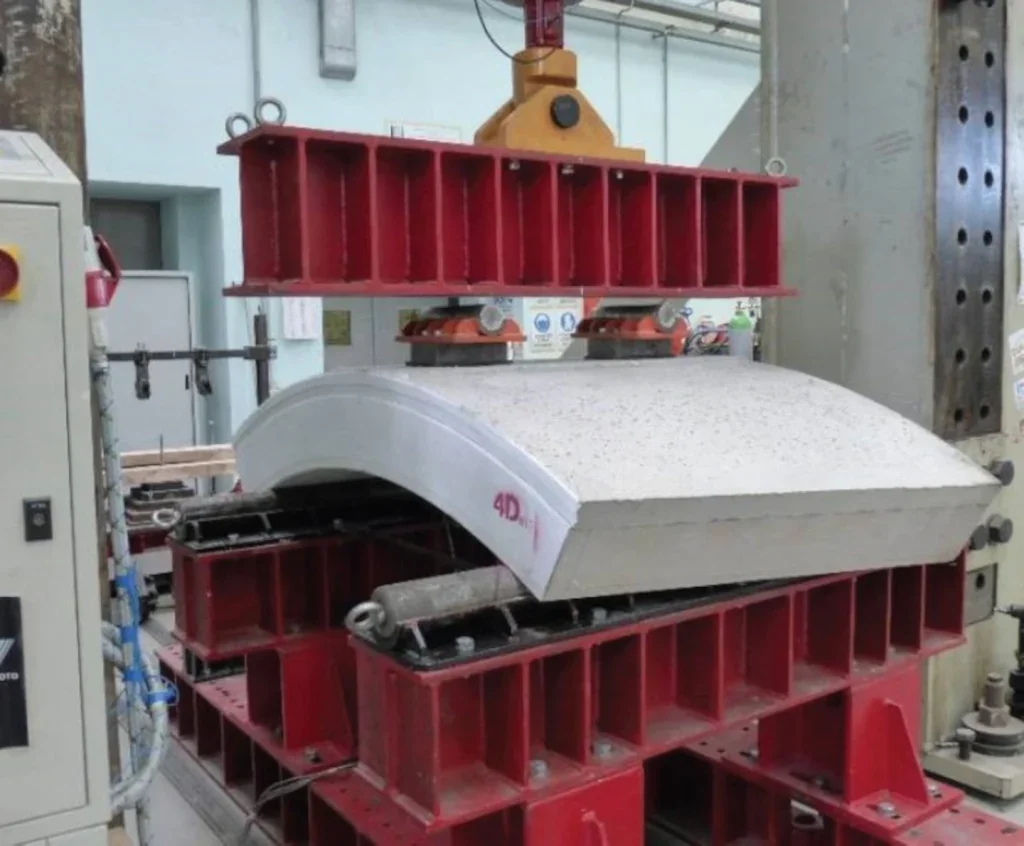

On the last section of our presentation, we covered the advantages of using steel fibres for crack width design, from the methodology based on EN 1992-1-1:2023 where a hybrid reinforcement is used (steel fibres + rebar), to obtaining a solution with reduced stress in rebar, leading to smaller, more distributed cracks.

IJboulevard Central Station, in Amsterdam, provided a case study to discuss. It is an underground bicycle parking garage where 4000 Amsterdammers and tourists can park their bicycles. IJboulevard is a hydraulic engineering project, an immersed tunnel, where the outer walls has a crack width-driven design, which allowed for a 10% – 20% cost saving and a potential reduction between 20% to 30% CO2 emissions with a hybrid SFRC design compared with a traditional steel reinforcement design, while maintaining the same crack width performance.

CONCLUSION

Throughout the workshop, the young engineers posed insightful questions, leading to dynamic discussions and a deeper understanding of the topics covered. The event was a testament to the importance of knowledge sharing and collaboration in advancing the field of tunnelling.

Bekaert is grateful for the opportunity to work with BTSYM and to contribute to the professional development of the next generation of engineers. We look forward to future collaborations and continuing to promote sustainable and innovative solutions in the industry.

BTSYM: WORKSHOP VIEW

Participating in the workshop organised by Bekaert and the British Tunnelling Society Young Members (BTSYM) on 20 March 2025 was a truly enlightening experience.

As a young engineer keen on tunnelling innovations, I found the event to be highly informative.

The morning sessions delved into the properties and benefits of steel fibre reinforced concrete (SFRC), including its tensile strength and crack control capabilities. The discussions on testing methods and the shift from temporary to permanent sprayed concrete linings were particularly insightful.

We explored what can be achieved with SFRC in various tunnelling applications, such as SCL excavations, and discussed the importance of crack control and durability. We also learned about potential pitfalls to watch out for, such as ensuring proper mix design and quality control to avoid issues like inadequate bonding.

The afternoon’s practical session stood out as the highlight. Using Bekaert’s software to design segmental linings and hybrid designs for cut-and-cover tunnel slabs/walls was both engaging and fun. The interactive discussions and questions from fellow attendees enriched the learning experience.

The workshop highlighted how the applications of SFRC can differ significantly depending on the project requirements. For instance, the design considerations for segmental linings in deep tunnels can vary greatly from those for cut-and-cover tunnels, where factors like load distribution and environmental conditions play a crucial role. This nuanced understanding of SFRC’s versatility and limitations was invaluable.

As a member of the BTSYM subcommittee, I was particularly proud to see the enthusiasm and engagement from all participants. The collaboration with Bekaert allowed us to offer a unique learning experience that combined theoretical knowledge with practical application. It was rewarding to witness the dynamic discussions of young engineers to explore sustainable and innovative solutions in tunnelling. This event highlighted the important role of such workshops in fostering professional growth and advancing our industry.

Author

Jess Xu – AtkinsRéalis – Ground Engineering & Tunnelling, and Member of the BTSYM subcommittees