In late October the much delayed Hindhead tunnel A3 trunk road improvements finally got the go ahead from the UK government.

Stephen Ladyman, Transport Minister, announced on 27 October that the government was committing US$705.5M to the works to improve the last remaining single carriageway section of the A3 between southwest London and Portsmouth to a dual carriageway. The scope includes 1.9km of twin tube tunnel under the Devil’s Punch Bowl site of special scientific interest (SSSI) in a bid to mitigate negative impacts on the environment.

Earlier, hopes had been raised for the scheme, which had been subject to further review, when it was included in a programme of schemes that the government announced on 6 July this year. It said it hoped to fund the scheme subject to completion of statutory procedures. The costs budgeted for the scheme have risen more than twofold since the early approval stages for the project.

The July announcement said that although wanting to accept the recommendations of the planning inspector to proceed with the published scheme by making draft work Orders, the Secretaries of State wanted to give interested parties the opportunity to comment on the increased cost and its change in economic benefits. T&TI learnt that 71% of responses indicated complete support of the published scheme, notwithstanding its increased costs.

The Highways Agency told T&TI that the scope of the project essentially remains the same as it was at the end of the Public Inquiry, except for the addition of a pedestrian underpass at the north end of the scheme. T&TI was told the main cost increase was due to construction inflation outstripping general inflation, which was previously used when calculating the scheme costs.

A Highways Agency representative explained further cost increases were due to the need to meet more onerous workplace exposure limits for nitrogen oxides and respirable crystalline silica generated by excavating through the sandstone along the route. Meeting the new requirements necessitated the use of more electric plant including ventilation plant together with reduced emission diesel plant. The source said, “plant costs have risen and rates of progress have slowed, resulting in increased costs”.

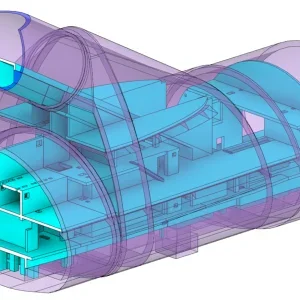

The horseshoe section tunnels will have a maximum internal diameter of 10.8m and feature cross passages at 100m intervals. They will be mined by excavator on a heading and bench. The lining is believed to be 150mm of steel fibre reinforced sprayed concrete, followed by a waterproof membrane and a 225mm thick cast in-situ non-reinforced concrete secondary lining. Lattice girders and spiling will be available if required.

Balfour Beatty will construct the tunnels following its award of an early contractor involvement (ECI) contract in 2002 since which time it has developed the design with the Highways Agency and consultant Mott MacDonald.

Initial environmental works are due to get underway next January with the main scheme being underway by April 2008 and the tunnel open to motorists in 2011.