Combined sewers serving cities worldwide are conveying more than their original designers intended – and not in a good way. As urban populations grow and once-in-a-decade rainstorms become routine, combined sewer overflows (CSOs) are discharging more and more untreated wastewater into rivers, lakes and oceans.

Citizens and legislators are unhappy with this spreading pollution. In the US, for instance, CSOs are subject to the National Pollutant Discharge Elimination System (NPDES) permitting programme, overseen by the Environmental Protection Agency (EPA). As violations become more frequent and severe, many cities are enlarging and extending their combined sewer systems.

BIGGER SEWERS FOR MODERN CITIES

Combined sewers are a logical way to handle domestic sewage, industrial wastewater and rainwater runoff, given that separate drainage systems are not usually practical. During normal rainfall or snowmelt, sewers store the extra water volume until it can be processed by wastewater treatment plants sized to handle average flows.

Yet extreme weather conditions are increasingly common. Many cities have outgrown sewers that were installed in the 1930s or even before, so CSOs may result from routine blockages and breakdowns as well as heavy rain. As a result, sewers are overloaded and discharges of untreated sewage have become distressingly frequent.

Mitigating the CSO problem requires building new sewers and enlarging existing ones. Diameters vary according to the required capacity, while tunnel lengths per project range up to 20km and more.

CHALLENGES FOR TUNNELLERS

The great length of many combined sewer tunnels increases the chances of encountering a range of ground conditions, so multi-mode and variable-density tunnel boring machines (TBMs) may be necessary.

As much of the work takes place in urban areas, shaft access is often restricted, and spoil disposal may be complicated. The need to match existing infrastructure also means that a single upgrade project may involve tunnels of several different diameters.

Successful sewer upgrade projects therefore require tunnelling experts with the resources and experience to support multiple large tunnels simultaneously over extended geographical areas. For projects of this scale, good local representation is key.

Herrenknecht has been active in sewer revamp projects all over the world. Some of the most notable have been in the US.

Steffen Dubé, President and General Manager of Herrenknecht Tunnelling Systems USA, Inc., says: “Approximately 40 percent of our large-diameter projects in North America are part of CSO projects.”

The examples below illustrate the challenges of recent such project work, undertaken in Washington, D.C., and Los Angeles.

A COMPLEX NETWORK IN WASHINGTON, DC

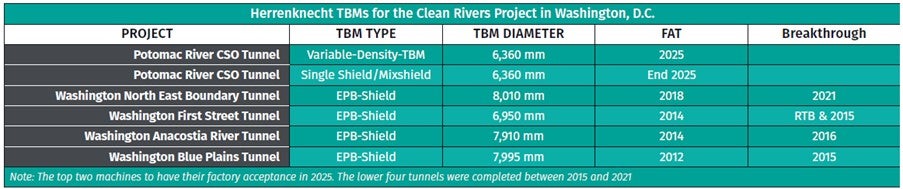

One landmark project in terms of its scale and complexity is DC Water’s Clean Rivers Project in Washington, D.C. Here Herrenknecht is managing the complete scope of the tunnelling project and providing all six TBMs (see Table).

The two TBMs that will be starting work in 2025 are multi-mode and variable-density machines, respectively, built to handle challenging ground conditions beside and beneath the Potomac River.

“This tunnel alone is scheduled to reduce the number of CSO events from 74 to four each year, and to cut CSO volume by 93% in an average year”, Dubé says.

In total, the Clean Rivers Project will deliver nearly 29km of new tunnels to provide intermediate storage and act as new feeder lines to the Blue Plains Advanced Wastewater Treatment Plant.

GOING LONG IN LOS ANGELES

Herrenknecht’s big project in Los Angeles involves a single tunnel, 11.2km in length, to carry secondary treated effluent from a treatment plant to outfall pipes on the coast. Its length, pressure and challenging geology combine to make the Joint Water Pollution Control Plant Effluent Outfall Tunnel another industry landmark.

The Los Angeles County Sanitation Districts serve more than five million people. The two existing tunnels that carry wastewater to the outfalls are more than 70-years old and do not meet current seismic standards. If they fail, untreated sewage could be discharged into surrounding waterways.

The revamp project will temporarily replace them with a single earthquake-resistant tunnel with a diameter of 5.5m to handle current flows while the existing tunnel are inspected and repaired. Ultimately, the new tunnel adds both redundancy and increases the overall system capacity.

Contractor Dragados USA used a Herrenknecht slurry TBM to manage the very variable ground conditions. Around half of the length passes through various soils; another 5% through weak rocks such as marl and mudstone; and, the remainder through weak and heavily fractured shale and sandstone. At this end of the tunnel the overburden depth increases to 150m, with 85m of hydrostatic head from the groundwater table.

Excavating the original tunnels was clearly a challenge to the engineers of 1937 and 1958, with records showing evidence of squeezing. With its adaptability and much faster forward speed, the Herrenknecht TBM has made the new tunnelling task simpler – but it remains a project to be proud of.

OTHER SIZES, OTHER COUNTRIES

In other CSO projects Herrenknecht has supplied machines for tunnels as large as 11m diameter. At the other end of the scale, the company’s CSO projects in the US have required TBMs below 5m in diameter, with pipejacking instead of the segmental linings used in the larger projects.

Although the US is a leader in terms of both awareness of the CSO problem and investment to mitigate it, the same issues affect many other countries worldwide. Canada’s eastern cities, for instance, share many issues with their US counterparts across the Great Lakes.

In the UK, awareness of the issue is behind that in North America, but generally ahead of the European Union countries, where around half of the sewers are of the combined type. Clearly, tunnellers will be in the sewer business for a long time yet as big cities worldwide upgrade their infrastructure to protect our oceans and waterways.