Adding to its software offerings for rock tunnelling equipment, Sandvik recently added to its iSURE systems to boost geological mapping in excavations underway, and also brought in its iNav total station as a further option in automating drill rig navigation in tunnels.

In the iSURE software, Sandvik has introduced a tool – iSURE Geo – to optimise excavation through real-time geological data as tunnelling advances. It can be used for tunnelling and mining, and give benefit to productivity but also safety, Sandvik says – and also a client which used its mine for field testing.

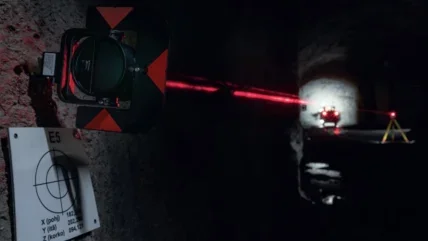

The iNav software is an option – even a retrofitting one – on Sandvik’s i-series drill rigs. Additional in-tunnel survey equipment is needed, though – such as a Leica total station and wall prisms. The entire system gives more independence to the rig operator, able to work in the cabin through data transfer from the survey kit.

iSURE

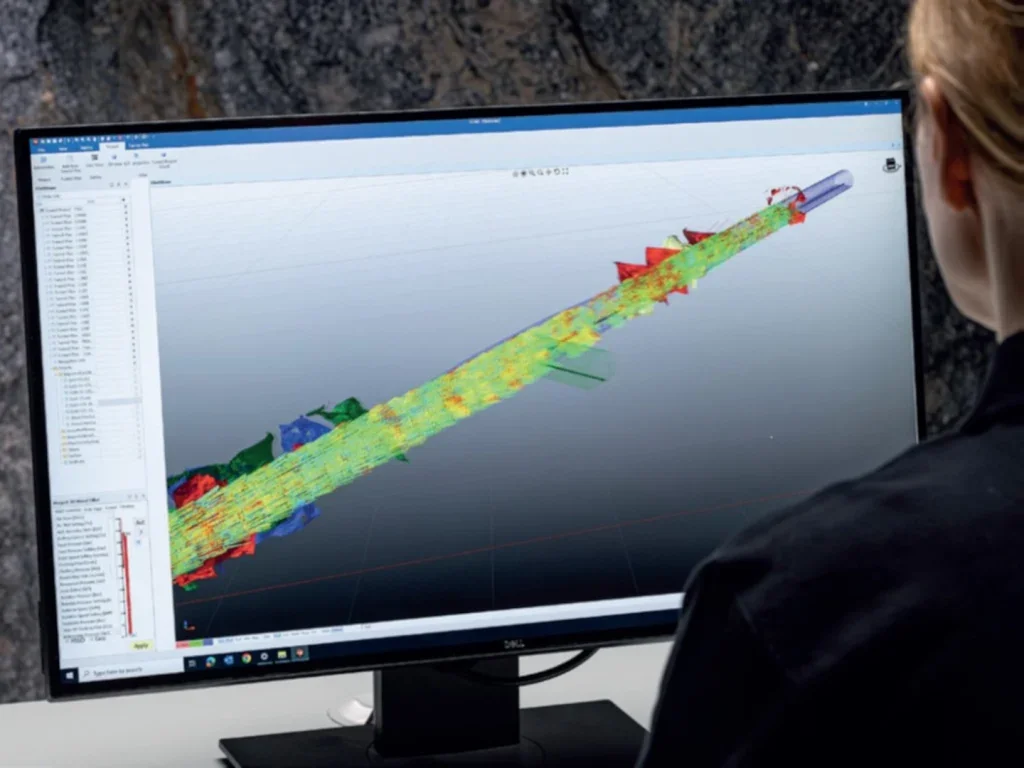

The iSURE Geo software tool has been launched to help optimise the excavation process in either tunnelling or mining operations by real-time handling of geological data obtained as the faces advance. Both productivity and safety benefits are possible. The software is part of Sandvik’s iSURE software, able to be employed with its i-series tunnelling jumbos and mining development drill rigs.

Sandvik says: “It delivers improves understanding of the local geological environment for optimised underground development mining and tunnelling operations.”

How?

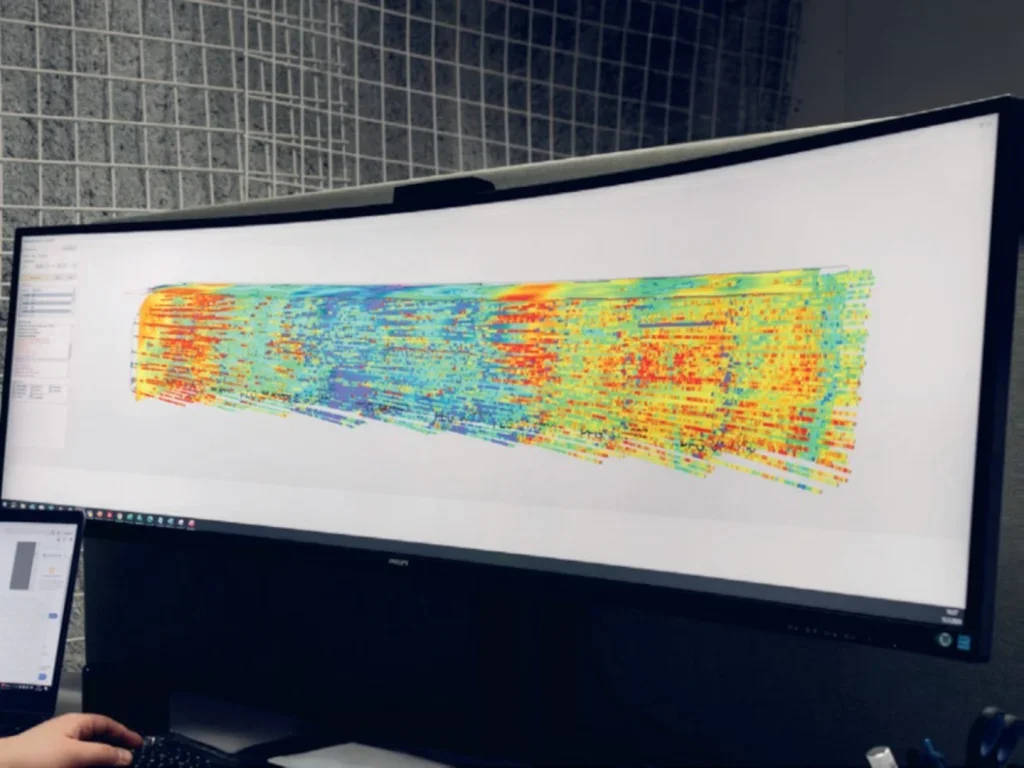

The software, onboard the rig, draws upon real-time drilling data to extrapolate and visualise to produce geological mapping information. Sandvik says ISURE Geo cab “assist to identify weakness zones requiring rock reinforcement, optimise use of explosives, plan the optimal location for stope openings, reduce over- and under-break, and produce comprehensive reporting.”

Field testing was performed at the Kittila mine, owned by Agnico Eagle, in Finland. The software was used to validate the existing rock mass conditions – giving “valuable additional information”, says Alexandra Heller, a structural geologist with the mine owner.

The result was detailed 3D imagery of rock conditions and geological properties in the local area.

Sandvik says the software can “help optimise the excavation process, anticipate potential challenges and improve safety through accurate geological information.”

Eemeli Bergstrom, another structural geologist working at the field test mine, noted the benefit of “getting very good quality confirming data”, helping both productivity and safety.

iNAV

Sandvik describes the iNav total station as the latest solution it offers for automating drill rig navigation underground where GPS is not available, and can be operated from the cabin by the rig operator – and can have survey data shared with other rigs on a project.

It is an optional feature on Sandvik’s i-series drill rigs. Leica surveying equipment to sit in the tunnel are part of the extras needed.

The company says: “The new method streamlines operations by enabling the operator to handle the navigation independently, even without prior surveying expertise.”

From the rig cabin, the total station device back along the tunnel is controlled directly, enabled by Bluetooth connectivity.

This link is compatible with the Sandvik’s DrillConnect app, it says – an app that transfers data on fixed-point coordinates from the survey computer to the drill rig’s systems.

Additionally, such survey data can be shared between other rigs in working on the tunnels of a project – which, says Sandvik, gives “efficient data sharing and operational flexibility.”

The jumbos that the iNav total station is optional on the i-series drill rigs – the DT923i, DT1132i and DT1232i – and, the company says, retrofitting can also be done. On other kit, the surveying system needs a Leica total station, Leica wall prisms and also a GeoCOM Robotics licence for full operation.