Fixed Firefighting Systems (FFFS) are an important safety feature in many tunnel designs. These systems can significantly improve safety by reducing fire intensity, lowering temperatures, limiting fire spread, protecting infrastructure, giving occupants more time to evacuate and emergency responders a safer environment to operate.

FFFS may be installed in tunnels based on regulatory requirements (e.g., NFPA 502, PIARC, EU regulations, AS4825 – 2011) or a fire risk analysis that evaluates specific tunnel conditions (e.g., tunnel length, traffic volume, evacuation constraints, and materials transport).

Large-scale testing of FFFS in tunnels is the most effective way to ensure their performance in real fire scenarios. Full scale testing helps to assess and evaluate:

- Fire Suppression Performance – How quickly and effectively the system can control or extinguish fires;

- Heat Reduction & Temperature Control – Evaluate the system’s ability to lower the tunnel temperatures and prevent structural damage;

- Smoke Management & Visibility – Measure how the system affects smoke stratification and visibility for evacuation and firefighting efforts.

The Reliable® TNL280 Nozzle has recently undergone a comprehensive series of large-scale fire tests, demonstrating its exceptional capabilities in managing and extinguishing fires in high-risk scenarios. This series included five distinct tests, each designed to evaluate the nozzle’s performance under different conditions and provide valuable data for various applications, particularly in vehicle tunnels.

Simulated fire loads (wood pallets and fuel trays) were used to recreate fire conditions during four of the five large-scale tests conducted. One unique feature of the Reliable test series is that fully-charged electric vehicles (EVs) were used during Test 5.

BACKGROUND

The Reliable TNL280 Nozzle is a cULus Listed nozzle in Listing group VGYZ that has been tested and listed in accordance with UL 2351, ‘Spray Nozzles for Fire- Protection Service’.

Although a myriad of tests is required to obtain the cULus Listing, a fire test was not one of them. The cULus testing ensured that the nozzle coverage area published in the documentation and the average collection through the coverage area provides +/-15% of the average water spray density.

The TNL280 Nozzle had already successfully been used in numerous road tunnel projects, including the WestConnex in Sydney, New South Wales, Australia. WestConnex is the longest road tunnel in the southern hemisphere.

During commissioning pan testing, it was proven the design density of 10mm/min was being delivered to randomly spaced pans.

However, UK road standard CD 352 requires a fullscale fire test or alternatively computational fluid dynamic (CFD) modelling. Recognising the limitations of CFD modelling, the decision was made to undertake a full-scale fire test.

TEST FACILITY

Testing was conducted at the Applus+ facility in Asturias, Spain, which is one of a handful of appropriate facilities for tunnel safety testing in the world. The test tunnel was approximately 1969ft (600m) long, 17ft (5.2m) high, and 31.2ft (9.5m) wide. The Applus+ test facility had the ability to provide forced ventilation through the entirety of the tunnel length.

FIRE TEST SCENARIO OVERVIEW

There were five tests run in total. Four were conducted with the standard test commodities described in the SOLIT2 protocol, and the final test was run with three Model 3 Tesla electric vehicles and one internal combustion engine (ICE) vehicle. The two standard test commodities were wooden pallets and a single test with multiple pools of diesel fuel.

150 MW Wood Pallet Fire Tests

Fire Tests 1-3 were conducted to represent a large heavy goods vehicle (HGV). The commodity was 420 wooden pallets arranged on an elevated platform approximately 4ft (1.2m) above the floor, to a height of about 8.9ft (2.7m). On the upwind side of the test commodity was a steel plate to represent a ‘cab’ of the truck. The potential heat release rate if all commodity was consumed is approximately 150 MW (512 million BTU/hr). Located 16.4ft (5m) downwind of the end of the test commodity was a target array elevated to the same height as the commodity. The direction of air flow was from south to north. The air velocity within the tunnel will be described in detail but was most commonly set to approximately 9.8 ft/s (3 m/s). It was elevated in a single test to a nominal 13.1 ft/s (4 m/s), averaging 4.7 m/s.

60 MW Flammable Liquid Fire Test

Test 4 was conducted to represent a pool fire. The pans in this test are 6.6ft (2m) x 5.2ft (1.6m) in size. Eight pans were simultaneously ignited at once with no barrier. A malfunction of the onsite water supply caused an unacceptable delay in water delivery to the nozzles, but the data provided valuable insights.

Electric Vehicle Fire Test:

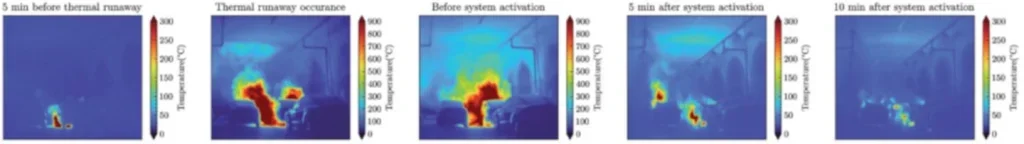

Test 5 in the series included three Model 3 Tesla electric vehicles in the configuration below as well as an ICE vehicle located upstream of the ignition car. A small pool fire of diesel fuel located directly under the battery casing was the ignition source. The pool fire was small but concentrated to ensure only localised heating of the battery.

SUMMARY

The Reliable TNL280 Tunnel Nozzle has demonstrated its efficacy in controlling fires in various challenging scenarios. The comprehensive testing conducted at the Applus+ facility in Asturias, Spain, has provided valuable data for tunnel designers and fire safety professionals. The nozzle’s performance in maintaining tenable conditions and controlling fires upon activation makes it a reliable choice for tunnel fire protection systems.

The testing objectives were successfully met, providing valuable insights into the nozzle’s performance in real-world applications. The data obtained from the tests will aid tunnel designers in smoke control system design and ensure the safety of egressing occupants and firefighters.

Overall, the Reliable TNL280 Tunnel Nozzle has proven to be an effective solution for tunnel fire protection, capable of handling various fire scenarios and maintaining tenable conditions. The comprehensive testing and positive results highlight the nozzle’s reliability and efficacy in real-world applications.

AUTHORS:

Greg Wilson is Technical Services Manager, ANZ Region at The Reliable Automatic Sprinkler Co. Inc. Phil Friday is Vice President, Product Technology. John Desrosier is the Manager of Product Analysis & Engineering.