E4 Förbifart Stockholm translates to English as the Stockholm Bypass; which somewhat understates what it is. A big project.

“Actually it is a huge project,” says Björn Stille, who was Design Manager for Rock and Grouting Manager with Afry/Aecom JV on the project. The JV supported the client as design consultant.

Stockholm Bypass is 21km in length with approximately 18km underground (tunnel lengths of 16km and 1.8km, respectively).

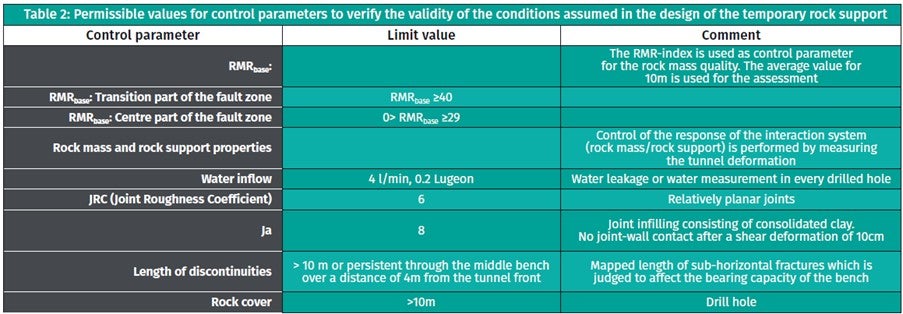

In tunnelling terms, double that distance given the twin main tubes. Then, add in the tunnelling works for cross passages located every 100m along the main tunnels, and spaced at 150m intervals on the ramps – of which there are many, along with a few access tunnels for the construction phase. The total length of tunnelling on the major road project in the Swedish capital is about 55km.

The project will carry three lanes of traffic in each direction. There are six interchanges. The route passes under Lake Mälaren, and does so at a depth of 65m below water level.

“It is twice as long as Sweden’s previously longest tunnel, and that one is a rail tunnel,” says Stille. This will be the world’s third longest road tunnel that is part of the infrastructure of a city.

CAPITAL TRAFFIC CHALLENGE

Stockholm, at present, has major road traffic problems. The current motorway, and Stockholm’s main traffic artery, is called Essingeleden. It became operational in 1967, shortly after Sweden switched to driving on the right-hand side of the road. It includes a 210m-long tunnel, the Fredhallstunneln, which lays claim to be one of the busiest in Europe.

Essingeleden itself is the busiest road in Sweden. It was designed for an estimated 80,000 vehicles a day and currently takes around twice that rate. It is, therefore, heavily congested, subject to delays, severe wear and tear, and there is frequent need for lane closures for maintenance. It is also subject to a congestion charge, money from which is helping to pay for the Stockholm Bypass – the cost of which is projected to be SKr 51.0 billion–Skr53.5 billion (US$5.1 billion–US$5.4 billion).

DEVELOPING A SOLUTION

As well as being huge, Stockholm Bypass has been a long time coming. It has been in planning, in various forms, since 1966. Permission to build was granted in 2009 and the project has been under construction since 2014, though there was a pause of several months thereafter following elections and a change of government before works restarted, in 2015.

Stille joined the project in 2017. “That was in what you might call the middle of the process,” he says.

Each tunnel is about 17m wide – “actually 16.4m with some over-blasting,” he says. “You always take a little more rock when you drill and blast.”

GEOLOGY AND TUNNELLING

“It is a drill and blast project rather than excavated by TBM; the Scandinavian geology rather dictates that,” says Stille.

Geologically, the area has hard crystalline rocks, gneiss and granites – “fairly old – about 2 billion years,” he says. “So as an old rock it has gone through a lot of different tectonic sequences. A lot of things have happened to it. But the matrix is hard and of good quality, generally speaking.”

Such rock is hard to tunnel through; the payback is that, once tunnelled, the tunnel has strength. For most of the route of the Stockholm Bypass the rock walls are self-supporting, he says.

“It doesn’t really need support in a global perspective,” he adds. “But we may have wedges of rock that could move, or we may have blocks that could fall out, and those we support with rockbolts.”

He continues: “Of course, there could be smaller blocks as well, and something could happen to those over time, so we do support the surface with shotcrete. But that is only to carry fairly small loads. Generally speaking, the shotcrete is only about 50-75 millimetres thick. It is only to protect against the smaller rocks falling.”

PROBE AND CORE DRILLING

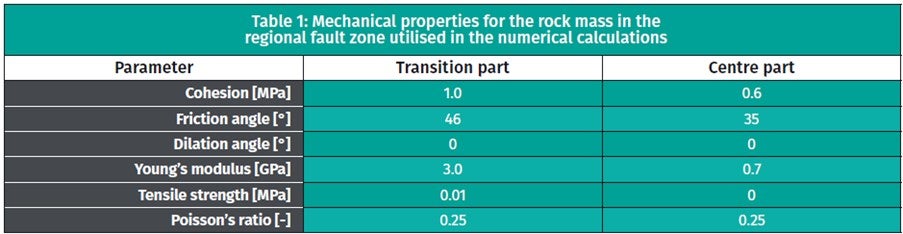

Stille says: “If you look at the topographical map you see we have the hills and we have the valleys. And the valleys are under water – under Lake Mälaren and its branches. We have altogether three lake passes to tunnel. And those parts are not only under water, but are also the parts where we would expect to have some sort of regional faults and poor rock.

“The exact geology quality is, of course, fairly difficult to predict in advance but in a general way we can predict that we will have a failure zone in these areas.”

After the topographical studies and the geophysical surveys there was a lot of probe drilling undertaken “to see what was really there,” he says. “It turned out that the rock cover was not super-large everywhere. The maximum cover was 70 or 80 metres, and at the lake passages it was only between 15 and 20 metres at the deepest points of the lake – and we could not be certain that we were sampling at the deepest points. In some cases, by tunnel entrances, there was no rock cover at all, only soil.

“So, then we did core drilling, to get the cores from the areas where we suspected that we had poor rock.”

The cores showed that in those fractured areas, under the lake, there were sometimes large voids.

“These were really important. They were not representative of the whole – mostly we had very good rock – but they were a problem that needed to be solved,” he says, as wide tunnels were planned.

“In areas where we had little rock cover, or where we had these regional fault zones with very poor rock, we added final support with cast-in-place lining. So, we excavated first, then installed rockbolts, then a shotcrete lining, and, finally, a cast-in-place lining,” he says. “Of course, we needed space for all that, so in those areas the tunnel was wider, around 20 metres.”

GROUTING

Stille says: “The most difficult part was going through the fracture zones under the lakes with heavily weathered rock mass.”

Water ingress would of course have been potentially disastrous.

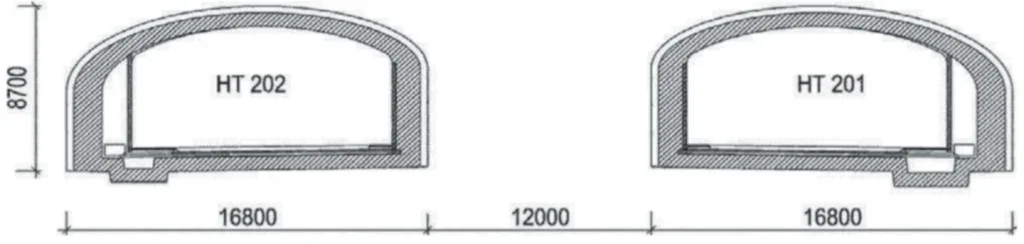

“That is one of the reasons why we chose drill and blast. It was not only because the rock is of good quality; it is also because we thought that in those areas we could secure the water leakages, prior to excavation, with cement grouting,” he explains.

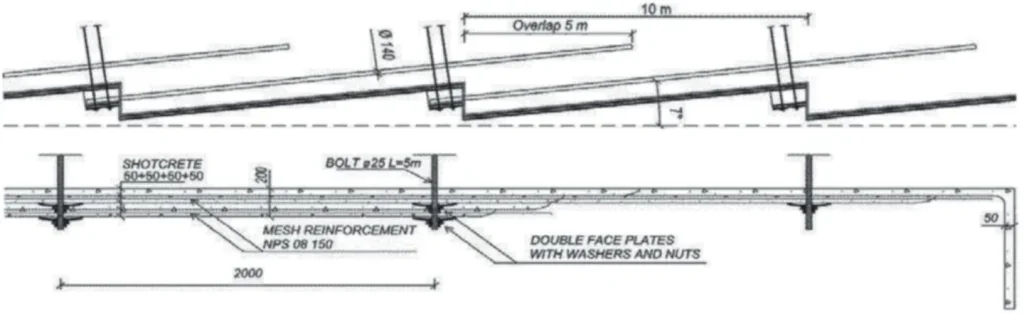

“The grouting was performed through drilling long grout holes, ahead of the tunnel in a fan shape around its circumference, and then injecting grout with a grain size of between 20 and 30 micrometres. The grout spreads around the holes of course.

“The main reason we did the grouting was to make sure that we had a good transfer of loads from the rock without a lot of deformations. We wanted to have good contact between tunnel and rock.

“But it has the secondary function as well, of sealing the fractures and stopping water seepage which was useful but not the primary reason for grouting.”

RISK AND TOOLBOX OPTIONS

Nothing in tunnelling is certain. Risk needs understood and managed.

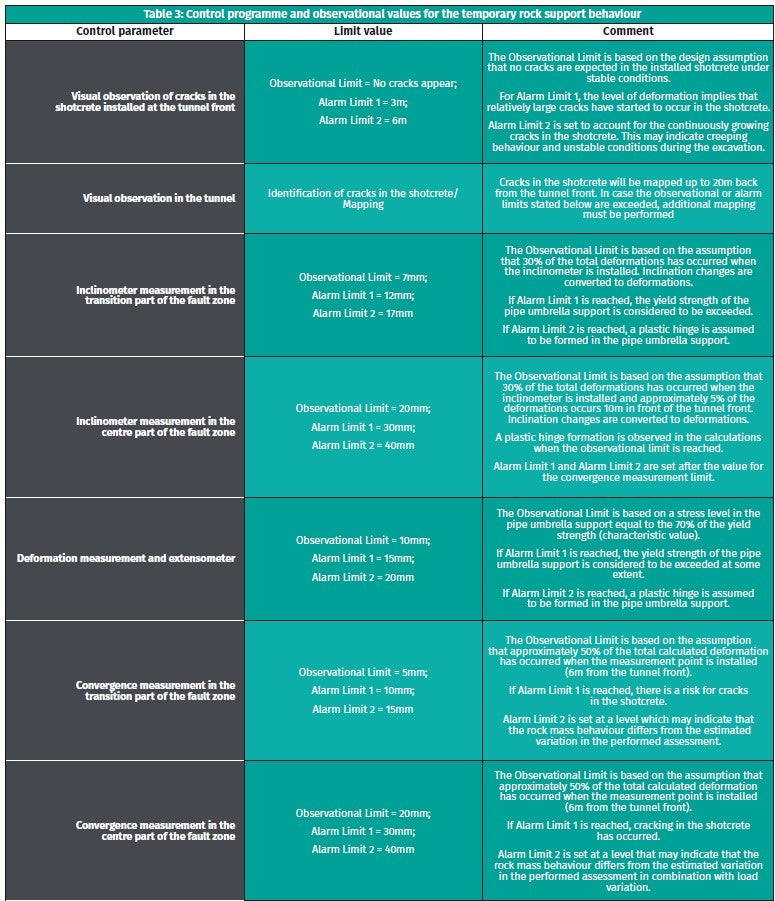

“Where the preliminary investigations gave us some information about the rock, we did risk assessments, and that of course includes the risk of encountering poor conditions,” Stille says. “So, you look at those risks and define proper mitigations for if and when you come across them.

“We came up with a sort of a toolbox of various measures to how handle various types of risks,” Stille adds.

He continues: “You never know exactly what you have ahead of you. Sometimes you encounter poor rock even though you haven’t expected it. Then you adjust your support and maybe even the grouting scheme for water tightness, in accordance with the geological conditions. I think it’s important to note here that there were no really unforeseen conditions. Even though some parts were really poor we were prepared for them.”

Passing below lake had more risk.

“The risk level was very high because the consequence of a tunnel failure could be enormous,” he says. “But we adjusted the technical solution and the design with regards to that the level of consequence.”

It was a fairly conservative approach, he comments.

“Also, as we went forward, we included very many steps and decision points,” he says. “One of the mitigations to make sure that we took adequate measures with regards to risk was to change the organisation during those passages of the tunnelling.

“We included all the disciplines, all the specialists; and, every week we would gather the contractor, the client and the designer, all sitting together and going through the past week’s work and seeing what it had told us of the geological conditions with regards to the identified risks: do we need to make any changes to the design, or to make some adjustments in procedure? Everything like that we discussed.

Stille says: “This happened at specific times, and when we reached specific areas. Sometimes we were excavating at the rate of less than 10 metres in a week; it takes a couple of days just to drill the pipes, and then you have to grout it and excavate. It was fairly slow progress in those parts but it meant that we had a lot of conferences for every metre dug, so that reduced the risk.

Most tunnelling contracts in Scandinavia are buildonly, not Design and Build, he says, and this was the case also for Stockholm Bypass.

“Long sections of the tunnels were quite basic. We knew which types of failure mode to expect. There may have been a little more fractured rock or a little less, but we knew that rockbolts and shotcrete would be sufficient. In the fractured rock zones the spacing between the rockbolts need to be smaller, so from 2 metres centre to centre they go down to 1.5 metres, in some cases.

“We identified some parts that needed more design work, more support, and more extensive grouting; and those we treated separately,” he adds.

“We had also had some parts where we didn’t have any rock cover, and in those cases we had choices. Open cut was the simplest and cheapest, but some areas of the Bypass go under an environmentally sensitive area where that was not possible. In those areas we could do some work but we were not allowed to make any permanent changes to the surface. And, it was important to the client to not have a visible presence on the ground.”

Challenges above ground as well as below.

“That gave us some problems, as cut and cover was ruled out,” Stille continues. “What we were able to do in some places was jet grouting: you inject the soil with grout under high pressure, using a rotational head, so that you break up the soil and it gets mixed with the cement slurry.

“The muck was removed by conveyor, some to barges, some to dumpers or lorries. What happened to it after that differed. The chemical composition of the rock mass was tested every hundred metres of tunnel. Depending on the result, some was used for landfill and some we could sell to a contractor who used it for roads and foundations.”

EXCAVATION NEARS COMPLETION

Tunnelling excavation is mostly finished on Stockholm Bypass. In addition to his work in the design consultancy JV, Stille was also a Technical Director with Aecom Nordic AB. He finished his most active onsite engagement on the Bypass in 2022 but has remained engaged with the project as an adviser on some final aspects.

His own consultancy (TriEng – short for Tunnel, Rock and Infrastructure Engineering) also works on other projects. Projects glide into one another, he observes.

“I have been working on the new Stockholm metro, and on a repository for low- to middle-grade radioactive material. We are excavating large caverns for them in the middle part of Sweden.”

On Stockholm Bypass, the focus of work is turning to fit-out.

He says: “The installations and fitting out have still to be done – that is everything from the water and sprinkler systems for fire protection, and ventilation, and electrics – there will be a lot of electrical signalling involved, traffic lights and so on.

There are emergency cross-passage about every 100 metres along the tunnels, and these will have huge numbers of detectors in them, for smoke or water-leaks and so on.

“We will put more inner linings in, not for stability but for the sake of the drivers who use it,” he says, as 17km is a long way to drive. “It improves the experience and safety if you can orientate yourself with some kind of variety as you progress. So it will not all be naked rock or shotcrete.

“For the same reason, the cross-passages are all marked with names as well as numbers,” he says. “It will give you some idea of where you are in relation to the surface above you.”

Stockholm Bypass is due to be fully operational in 2030. One part, the stretch between Häggvik-Hjulsta, could be open in 2026.

QUESTIONS AND ANSWERS WITH CLIENT’S PROJECT MANAGER

Camilla Magnusson is Trafikverket’s Project Manager for the Stockholm Bypass. She discussed some of the complexities of co-ordinating such a large-scale construction project with Julian Champkin

T&TI (Julian Champkin – JC): How long have you managed the project?

Trafikverket (Camilla Magnusson – CM): I have been in charge of this project since the Autumn of 2022. When I joined, we were in full production and had about one year left of hard rock tunnel driving. I had the honour of experiencing the tunnel breakthrough, which was a very important milestone for us.

JC: How have you co-ordinated the different requirements and people on the large project?

CM: This is a huge project, or actually a programme, consisting of several large projects with around 60-70 contracts running more or less in parallel. One of the major challenges has been, and still is, to get everyone moving in the same direction and understanding the dependencies we have internally. That is always a challenge in projects of this size. A small delay in one part can have major consequences for other projects, so we have to avoid sub-optimisation and tunnel vision (pun intended).

To make sure we work in the same direction as one single programme, we have, among other things, established a central organisation that coordinates timelines and production for all projects and contracts. This gives us a clear picture of all the dependencies between projects and enables us to identify problems and challenges at an earlier stage than what would otherwise have been the case.

We also consistently work with creating a transparent culture, increasing the understanding for each other’s challenges and the impact our work has on each other. Needless to say, an important factor when working as a team is that people not only enjoy their work but also feel appreciated and seen. This is an area that we continuously address with all leaders in the programme.

I am very, very proud to work with this team; the people are highly competent, and they are also able to step outside of their own responsibilities, if needed, to ensure that we succeed as a team.

JC: How are environmental issues addressed?

CM: In each respective contract, the Swedish Transport Administration has set requirements for the contractor to work towards reducing carbon dioxide emissions during the construction phase. Savings can be achieved either by selecting materials with a lower carbon footprint or by finding design solutions that require less use of climateimpacting materials, such as steel, concrete, and fuel.

Each contractor must develop an action plan describing how they intend to meet this requirement, and the Swedish Transport Administration has subsequently conducted annual follow-ups on the work. Once the project is completed, the contractor must submit a climate declaration detailing how savings have been achieved and what measures have been taken to meet the goal.

When we procured contracts for the Stockholm Bypass project, there were not many electric construction vehicles available, so we were unable to set requirements for their use at that time. However, the Swedish Transport Administration is actively working on these issues at a central level.

JC: Any unforeseen problems? If so, how were they resolved?

CM: In a project of this size, you always meet unforeseen problems at some point. We have, historically, had challenges with the quality of the rock as well as water leakage. Not impossible challenges but it has forced us to rethink and try other methods.

JC: JC: What design measures are used for long tunnel drives?

CM: The aesthetic design is a direct result of the E4 Stockholm Bypass’ Design Programme, which was a part of the Final Design Plan of the E4 Stockholm Bypass, from around 2011. The Design Programme contains guidelines for the architectural design of the tunnel, and surface road areas of the E4 Stockholm Bypass.

Regarding the underground tunnel exits, they were subject to a design competition which resulted in five winning art concepts, by three different artists. The purpose of the Design Programme covers several criteria and design aspects:

- To help with orientation underground, e.g., by associating the tunnel exit to the surface location of the exit

- To mitigate the negative aspects of monotony from driving in a long tunnel

- Every cross-passage is designed to have its own identity, with names and numbers, and a dedicated spotlight highlighting the green cross-passage portal against the grey tunnel wall

- Artwork in the tunnel must be adapted to be viewed at high speed

- To act as complement to the more regular safety systems, such as signage and lighting

- Artwork has been designed so as not to distract drivers or affect road safety

Trafikverket (Swedish Transport Administration) has a long history of incorporating aesthetic design in complex road tunnels, e.g., in the Southern and Northern Link tunnels

The Q&A was edited for space and brevity.