Advancements in Building Information Modelling (BIM) and the subsequent emergence of Digital Twins have widespread implications for tunnel owners, designers, engineers and contractors.

BIM already directly influences the way assets are designed and built, reducing rework and facilitating more collective collaboration. Digital Twins, or ‘live models’, have the potential to push that evolving digital framework to a whole new level.

While many might see the primary value of a Digital Twin in its ability to manage an asset in real-time, it’s much more. This ‘model of truth’ becomes a basis from which owners and project partners can simulate asset behaviour and drive improvement with an emphasis on safety, community and environmental outcomes.

FROM OUTCOME TO OPTIMISATION

For a growing number of transportation entities, BIM or the utilisation of a 3D model is an essential piece of a collaborative design-to-construction process, and for some, is an integral piece to maintenance and operational activities.

The US Federal Highway Administration (FHA) recently said: “Using digital data such as 3D models to build road projects is becoming an industry standard. Sharing the design model and associated digital project data allows agencies and contractors to streamline project delivery and contract administration and to collaborate on challenges ‘virtually’ before they get to the field.”

European countries are leading the way in the investment and implementation of BIM.

Norway’s highway authorities already rely on what they call a ‘constructible BIM’, a model delivery that has been required for many years. By demanding BIM, these organisations have experienced significant cost reductions in the form of fewer errors and fewer change orders. This also includes fewer conflicts, because all parties understand a model and hence have a better overall picture of the project.

Essentially, BIM provides a better project outcome. The next step would be the transition to a Digital Twin for optimisation. The difference between outcome and optimisation is an important distinction.

buildingSMART International (bSI) describes the difference between BIM and Digital Twins very clearly: successful BIM processes and frameworks help project teams establish a clear project vision that supports business outcomes before design commences or work begins on site. Digital Twins help visualise, monitor and optimise operational assets, processes and resources by harnessing live data.

Pe bSI: “At its core, a Digital Twin can be an output of a BIM process and is essentially a ‘living’ version of the project or asset view that BIM processes exist to create – able to evolve and transform using real-time data once the asset is in use. That Twin will act both as a single source of truth for the asset throughout its lifecycle, and as a blueprint for future innovation and improvement – taking a process and elevating it into an evolving project.”

While it might seem a relatively straightforward process to simply add sensors (much like monitoring) to tunnel infrastructure or even link to field-based solutions to gather live data, one of the foundational pieces that is still emerging in the process is standards.

A COMMON LANGUAGE

Standards have long been a familiar way for architects, engineers and contractors to communicate data across different systems and purposes. In today’s environment, the Industry Foundation Classes (IFCs) from bSI provide a universal 3D format. The IFCs define process, data and attributions for the effective utilisation of assets across an asset’s deliverable cycle.

To truly take advantage of BIM and Digital Twins in the tunnelling industry, we must have an IFC or equivalent standard. As a start, bSI has introduced the IFC 4.3 open data standard for horizontal assets, such as roads and rails. The IFC 4.3 standard incorporates infrastructure entities into the IFC schema. It defines standards for defining road length, width and depth, number of lanes, maximum speeds, material composition and location. An IFC is necessarily complex because it is attempting to model the entire constructable world in a common way across multiple organisations and varying software—in essence, it’s the foundation for interoperability.

This standard will be extended to tunnel entities in the next release, IFC 4.4. In the interim, the technology is readily available for transportation agencies responsible for tunnels to derive value from BIM and, what I might call, Digital Twin ‘light’.

THE CONNECTIVITY QUEST

For some, the cost to deploy BIM and Digital Twins may still seem too high – though the cost and complexity of continuing with conventional methods is rising.

Most commonly, transportation agencies will send engineers and surveyors out to inspect these assets—in today’s environment, with labour shortages a common concern around the globe, that’s a time consuming and costly effort. A true Digital Twin, one linked to sensors, can provide the data very quickly. Add in artificial intelligence (AI) and the analysis of that data becomes invaluable.

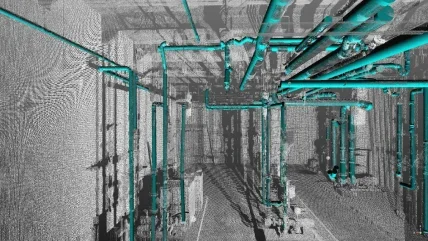

It’s one thing to create 3D data or models for use in an office environment. It’s a whole other challenge to take this data into the field, either on small data collectors or with the surveying equipment. Until recently, the construction industry really hasn’t had the capability to handle this type of data in a cost-effective, simplified way. That is changing. The field equipment that people use in the tunnels today are becoming much more powerful, allowing project teams to work directly from a model while still in the field.

On the Bergünerstein Tunnel project, Donatsch + Partner AG, relied on a collaboration platform to enable the seamless transmission of data and easy access to the most current design. For example, Donatsch + Partner was responsible for calculating excavation and shotcrete volumes. The team used laser scan data to create profiles for over- and under-excavation analysis that were compared to the 3D model to identify areas that required rework.

The cloud process allowed Donatsch workers to check the results in a timely manner and quickly catch errors or identify gaps.

Through this collaboration platform, Donatsch + Partner was able to connect design revisions and changes to all stakeholders seamlessly and uniformly, and provide enhanced deliverables to the client. The idea is to shape a Digital Twin-like environment, as the model is updated throughout the project providing data accessible to stakeholders to make more informed decisions.

The contractor has developed a platform, and a model, that will live through the lifecycle of an asset, including maintenance and operations.

IN THE FACE OF CHANGE

Whether roads, bridges or tunnels, our infrastructure is continually moving. Climate change is already having a direct effect on the behaviour and lifespan of our infrastructure assets, including tunnels. Tunnel geology is behaving slightly differently than it has in the last 100 years. With a digital twin, we can potentially anticipate movement outside the norm with automatic alarms, for instance.

National Highways, the highway transportation agency responsible for England’s Strategic Road Network (motorways and major A roads) is using a Digital Twin to improve its concrete roads. The mission of the programme is to replace end of design life and design load pavement. The group is using a living Digital Twin of the concrete roads to simulate asset behavior and improve safety and sustainability. Road condition data, including repairs, is regularly updated through a field data collection app provided to contractors. Further embedded sensors in the concrete measure water runoff quantities, temperature, moisture, dew points and CO2. With this data, the programme team can analyse the direct effect of external factors, such as climate change, on concrete behaviour that was never possible with previous methods.

Live connectivity, such as what National Highways deploys on concrete roads, is not common. Much of the data gathering is still largely manual where an individual gathers data in the field and returns to the office to process the data and then update the model.

The resulting updated model is an early form of Digital Twin, but not a true ‘living’ model.

In the future, data will be gathered and fed into a Digital Twin in ways we haven’t yet considered, say from cars driving through a tunnel. The value of a Digital Twin transcends the ability to live monitor an asset; it’s a powerful tool that will benefit the lifecycle of tunnel, improving the way an asset is constructed and maintained, reducing the costs that are inherent in our largely disconnected workflows between various project parties, and cutting the time to delivery. That said, while a ‘live’ Digital Twin is the higher goal, along the way the current versions provide enormous benefit to the lifecycle of a tunnel.