Setting the scene on tunnelling in China ahead of the World Tunnel Congress 2024 – to be held in Shenzhen, in early 2024 – is Jinxiu Yan, the immediate Past President of the International Tunnelling and Underground Space Association (2022-252) and Co-chair of the WTC2024 organising committee. As one of the country’s top tunnellers, she is also Vice President of Tunnel & Underground Works Branch of China Civil Engineering Society (CCES), and Chief Expert of China Railway Academy Co., Ltd. In this briefing for T&T, she gives an overview of the many projects and technologies that delegates can look forward to learning about in depth, next April, at the huge gathering.

WTC 2024 will be held over 19-25 April 2024, in Shenzhen, China | www.wtc2024.com

SNAPSHOT OF TUNNELLING IN CHINA Many of our international tunnelling colleagues are aware of numerous tunnel projects built and under construction in China. However, they might have a limited knowledge of the specific details. It has been 33 years since the 16th ITA General Assembly took place in Chengdu, China, in 1990.

Back then, as a young tunnel engineer in the organizing committee, I was fortunate to attend the 16th ITA General Assembly and WTC1990 (the 16th Annual Meeting and the International Congress). Now, as Cochair of the WTC2024 organising committee, I have witnessed the progress of China’s tunnelling technology and industry over three decades. I think it would be appropriate to say it’s time for our international tunnelling colleagues to return to China and see the developments since 1990.

By the end of 1990, mainland China had only constructed about 2,543km of traffic tunnels, including 2,359km of railway tunnels, 130km of highway tunnels, and 54km of metro tunnels. But, after 33 years of fast development, by the end of 2022 China had completed an impressive total of 56,768km of traffic tunnels, including:

- Railway tunnels: 17,837 tunnels, totalling 21,978km.

- Highway tunnels: 24,850 tunnels, covering 26,784km.

- Metro projects: 55 cities contributing to a total rail transit length of 10,291km, of which 8,006km (77.8%) are underground.

This indicates that China has multiplied its traffic tunnels construction by 22 times compared to the figures from 1990 (see Table 1).

It is worth noting that not only has the total length of traffic tunnels increased significantly, but also there has been a rapid growth in the construction of large tunnels, including extensive railway and highway projects.

Currently, there are around 12 long railway tunnels in operation, each longer than 20km (see Table 2), with an additional 26 tunnels of similar length under construction. The longest railway tunnel in operation is the 32km-long New Guanjiao railway tunnel, constructed at a high sea level. One of the large tunnel projects under construction is the 34km-long Gaoligongshan railway tunnel, employing both drill and blast (D&B) and tunnel boring machine (TBM) excavation methods, and passing through complex geological conditions.

As for road tunnels, approximately 18 tunnels, each exceeding 10km in length (see Table 3), have been successfully completed. The longest highway tunnel in operation is the 18km-long Qinling Zhongnanshan Highway Tunnel, constructed in challenging hard rock conditions and completed in 2007. At present, the longest highway tunnel under construction is the 22kmlong Tianshan Shengli tunnel, expected to be completed in 2025.

In terms of metro tunnels, by the end of 2022 there were 51 cities in mainland China with 243 urban rail lines, spanning a total length of 6,350km. It is noteworthy that 29 cities are each concurrently building more than three lines, 22 cities are engaged in projects with more than five lines, and seven cities are constructing more than 10 lines simultaneously. Over 23 cities are undertaking the construction of metros with total length of lines each exceeding 100km (see Figure 1).

The last 20 years were the fastest-developing period of the tunnelling industry in China. In addition to a large number of tunnels built, there are also around 20,000km of tunnels in total under construction, including 7,700km of railway tunnels. Even more tunnels are planned.

PROGRESS OF TUNNELLING TECHNOLOGY

The progress in tunnelling technology in China covers a wide range of projects, including railways, roads, metro systems, water tunnels, sewerage tunnels, storage caverns, and so on. Various tunnelling methods, such as conventional approaches, TBM methods, D&B, and immersed tube methods have been employed. The geological challenges faced on the tunnel projects has ranged from hard rock and soft ground to special conditions like Karstic geology, loess, high water pressure, rock bursts, squeezing ground, and methanerich environments. Valuable experience and lessons have been gained from constructing a multitude of tunnels under these varied and challenging conditions.

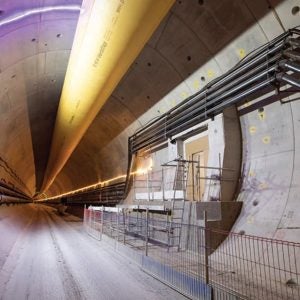

Innovations play a pivotal role in ensuring the fast and safe construction of these challenging tunnels. In terms of urban tunnelling, conventional methods dominated the 1990s, and then the trend changed to more mechanised methods. Constructing metro and urban underwater tunnels in soft ground using conventional methods proved challenging in sensitive urban environments. Thus mechanised methods have become the norm, in soft ground being constructed using TBMs, except for those with varying crosssections. Mainland China currently has around 5,000 TBMs, with some cities employing more than 50 TBMs simultaneously, and the number of TBMs in operation in several cities even exceeds 100.

In urban areas, the popularity of large-diameter tunnels has surged due to limited underground space available.

As of August 2023, China has 80 large TBM tunnels either built or under construction with diameters larger than 14m. Of these, 39 have been completed and are in operation, and 41 are under construction – the largest of which is the Ji’nan Huanggang Road Tunnel, utilising a 17.5m-diameter slurry TBM to excavate a 3290m-long section of the 5755m-long tunnel.

In the shield TBM market, there are primarily two categories: single-mode shield TBM and multi-mode shield TBM.

Single-mode involves only one excavation method, such as EPB TBM, Slurry TBM, or Hard rock TBM (open, shield type), while multi-mode offers combinations such as ‘Slurry + EPB,’ ‘EPB + Hard Rock TBM, and ‘Slurry + Hard Rock TBM’.

The 6.28m-diameter version of the three-mode TBM developed by CREG even allows seamless switching between modes, thus enhancing operational efficiency and safety. This technology has been successfully used to complete tunnel boring for the Luogang to Shuixi section of Guangzhou Metro Line 7 (see Figure 2), covering complex conditions on twin 1086m-long tubes passing through hard rock formations, soft soil layers, and working in densely populated areas.

To minimise the risks associated with tunnelling in challenging and complex geological conditions, geology prediction technology has been widely utilised in mainland China for both conventional and mechanised tunnelling.

Mechanised tunnelling, being significantly different from conventional tunnelling, is sensitive to substantial geological changes which makes it impractical to conduct traditional geological mapping at the excavation face. Therefore, various innovations have been made to enhance geological prediction for TBM tunnelling in China.

One of those innovations is the HSP217T Realtime Tunnel Geological Prediction System developed by China Railway Academy. This system can be integrated into and used for different kinds of TBMs (hard rock, EPB and Slurry) that are manufactured by different companies

The core innovative concept of the HSP217T prediction system lies in utilising the vibration signals generated during TBM boring as the signal source. The prediction process comprises three steps:

- signal emission: TBM boring generates and emits vibration signals;

- signal reception: geophones installed on the tunnel contour can capture and receive the vibration signals; and,

- system analysis and alarm: the host HSP217T module, mounted on the TBM, efficiently performs and completes these tasks.

Without the need for additional seismic sources, this system can detect and display geological conditions (see Figure 3) up to 100m ahead of the TBM cutterhead in realtime, thus greatly enhancing the convenience and efficiency of geological prediction.

To conserve a sustainable environment, the reuse of excavated tunnelling material has become a priority. Advanced treatment technologies and comprehensive sets of equipment for both hard rock and soil have been developed and widely employed in mainland China. The most challenging aspect is the treatment and reuse of material excavated by EPB and slurry TBMs, as this kind of material typically contains a high water content.

To solve the challenge, a specific system has been developed and manufactured by CRHIC for EPBexcavated material in China and was first used on Shenzhen metro Line 14, and is now being employed on many other projects in China. It can realise multistage separation, dehydration, and drying of residual soil, and produce aggregate, mediumfine sand, dry mud cake, and water, thus facilitating the reduction of transported excavated material. This solution not only promotes environmental protection but also enables the effective reuse of excavated material.

These developments will be discussed at WTC 2024, along with opportunities to have Technical Site Visits (see Box Panels 1 & 2).

Last but not least, the ITA’s 50thanniversary celebration at WTC2024 promises to be a memorable event. On the morning of 23 April, a special meeting will announce the ITA’s selection of the 50 global outstanding tunnel projects over the period, alongside various other celebrations.

Beyond technical exchanges, participants can look forward to a rich cultural experience in Shenzhen with the inclusion of diverse elements from Chinese traditional culture in the social events of WTC2024. It’s set to be an unforgettable blend of technical insights and cultural immersion.

WTC2024 IN SHENZHEN, CHINA

In 2024, it will be 34 years since the WTC1990 was held in Chengdu, China. As mentioned earlier in this article, during the past three decades numerous tunnels have been constructed in China, and various innovations have been developed to find better solutions for tunnel projects.

In the process, the Chinese tunnelling industry has received significant support from the international tunnelling community through the ITA platform. Experience gained from projects worldwide, new technologies, advanced equipment and materials have all played crucial roles in the construction of a large number of tunnel projects in China, especially those in challenging conditions.

In return, the Chinese tunnelling industry has also shared with the international tunnelling community its experience with intensive construction of various types of tunnels in different conditions. Undoubtedly, WTC2024 will be the best place and time to learn about what the Chinese tunnelling industry has accomplished over these three decades.

Under the theme of ‘Tunnelling for a Better Life’ and with 21 subtopics, WTC2024 has received around 1,000 abstracts from the tunnelling community worldwide, and 792 abstracts have been accepted by the Technical Committee. There will be five parallel Technical Sessions instead of four, as in previous WTC events. Many high-quality technical papers from China will cover innovations, state of the art of different tunnelling methods (conventional, D&B, mechanised, immersed tube, etc.,), solutions to challenging conditions, new equipment and materials, and more.

In particular, some Technical Sessions will focus on large tunnel projects under construction or newly built, with a special emphasis has been placed on having many large tunnelling projects in Shenzhen and its vicinity available for Technical Site Visits. These are:

1. Shenzhen-Zhongshan Link Immersed Tunnel (See Figures 7 & 8):

- Length: 6.8km

- Structure: Steel outer shell + concrete

- Dimensions: 46m wide, 10.6m high

- Notable Feature: The current world’s largest immersed tunnel of its kind.

- Project Timeline: Started in April 2018, expected to be open for traffic in June 2024.

2. Pearl River Estuary Tunnel of Shenzhen-Jiangmen Railway:

- Length: 13.69km

- Construction Methods: Conventional and two TBMs (diameter: 13.32m)

- Project Timeline: Construction began in July 2020, expected to be completed in December 2025.

3. Shenzhen Metro Line 14 (including Huangmugang Integrated Station):

- Line Length: 50.34km (Phase 1)

- Stations: 18 (all underground)

- Train Type: 8-car Type A, automated driverless technology, max speed 120 km/h

- Notable Feature: Huangmugang station designed as an ‘Urban living room’.

- Project Timeline: Construction started in January 2018, operational since October 2022.

4. Qianhai Integrated Transport Hub, Shenzhen (Largescale Underground Integrated Transport Hub):

- Lines Involved: Three metro lines (Lines 1, 5, & 11), two intercity railways

- Area: 20 hectares

- Floor Area: Approximately 2.159 million square metres

- Notable Feature: Underground hub with extensive surface properties.

5. Guangzhou-Dongguan-Shenzhen Intercity Railway (TBM Tunnel Project):

- Designed Speed: 160km/h

- Length: 14.5km

- TBM Method: Mainly being constructed using 13.27m dia. TBM

- Project Timeline: Construction started in 2021, expected completion in 2026.

- Note: Complex geological conditions and a sensitive environment add challenges to this central Shenzhen project.

6. Shatin Caverns, Hong Kong – Relocation of Sha Tin Sewage Treatment Works:

- Notable Feature: Largest caverns of their type ever built in Hong Kong.

- Dimensions: Span up to 32m, height up to 28m.

- Project Timeline: Construction commenced in February 2019, expected completion in 2031.

- Note: Project initiated by the Drainage Services Department to support sustainable development in Hong Kong, following public engagement and consultation.

7. Trunk Road T2 and Cha Kwo Ling Tunnel, Hong Kong:

- Two 14m-dia.TBMs concurrently utilised for the 3.4km-long dual two-lane trunk roads for Trunk Road T2

- Innovative technologies: accessible TBM cutterhead, real-time monitoring of disc cutters, and AI-supported tunnel drone inspection.

- Largest sizes of caverns in Cha Kwo Ling rock tunnels range from 20m to 30m in width and 10m to 15m in height.

- Part of the Route 6 which is going to be a strategic transport route that substantially helps reduce the current journey time between Yau Ma Tei and Tseung Kwan O.

WTC2024 will provide participants with opportunities to visit these interesting and challenging projects, and also learn about others (see Box Panel-2).

WTC2024 IN SHENZHEN: TECHNICAL SITE VISITS

In addition to the seven projects available for Technical Site visits (see Box Panel-1), some other large and challenging projects will also be highlighted during WTC 2024. They are:

Qingdao 2nd Undersea Road Tunnel, in Shandong Province:

Connecting Qingdao and Huangdao Island, (see Figure 5), this tunnel, when completed in 2027, will for a time be the world’s longest undersea road tunnel (length: 14.37km). Being built by D&B and three TBMs, the project consists of three tubes, including two main tubes with three lanes each, and one service tube. The distance between the two main tubes is approximately 55m, and the deepest point of the tunnel alignment is 115m below sea level. The project poses significant challenges due to its complex geology.

No.1 Daliang Mountain Highway Tunnel, in Sichuan Province:

At 15.3km in length, this tunnel is one of the longest highway tunnels under construction in mainland China. It comprises three tubes, with two main tubes and one service tube. The main tunnels are constructed using D&B, while the service tunnel employs a hard rock TBM. This project, the first highway tunnel in mainland China to utilize a TBM (see Figure 6), successfully completed its service tube in September this year. The main tubes are still under construction. The project is expected to be completed and operational in 2024.

Gaoligong Mountain Railway Tunnel, in Yunnan Province:

This 34.5km-long project consists of one main tunnel and one parallel pilot tunnel, constructed by both conventional methods and TBM. The geology poses extreme challenges, including three ‘highs’ (high ground temperature, high ground stress, and high seismic intensity).