“SippTech is honored to partner with SAK. Their knowledge, experience, and innovative thinking in the pipeline rehabilitation industry offers the ‘perfect storm’ of opportunity for Sipp Steel. SAK has been expertly delivering the most advanced, field proven products to rehabilitate pipes globally for years.” Weisenberg stated.

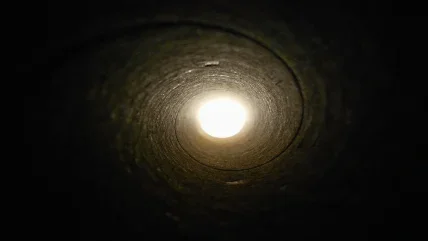

Sipp Steel is a three-component composite lining system that entirely overcomes the limitations and inconsistencies present in prior SIPP technologies. This is made possible by utilizing a combination of specific and cooperative machine learning technologies, including computer-vision, LIDAR ultrasound, RF, Wi-Fi, gyroscope, and accelerometer, to precisely navigate and apply the SippSteel composite inside of the pipe. The result, the manufacturer said, is the installation of a structurally independent lining system with reduced construction time, minimal consumer disruption, lower costs, and a small environmental footprint.

“We look forward to working together with Sipp Tech to expand this technology throughout the United States. To date, we have not seen a trenchless rehabilitation technology possessing such efficacy and versatility for the pressure pipe industry,” added Jerry Shaw, president of SAK.